2025 Guide: How to Choose the Best Automotive Spot Welder for Your Needs

Choosing the right automotive spot welder can seem daunting. With many options available, making an informed decision is crucial. Expert John Smith, a seasoned professional in the automotive repair industry, once said, “The right welder can make or break the quality of your work.”

In today’s automotive landscape, a reliable spot welder is vital. These tools allow for precise joining of metal parts, ensuring durability and strength. However, many users overlook key features. They might focus solely on price or brand reputation. This can lead to disappointment later on.

Consider your specific needs. Not every project requires the same level of intensity or power. Understanding your typical tasks can guide your choice. Remember, the right automotive spot welder is an investment. It impacts both your efficiency and work quality. Reflect on what matters most to you before making a decision.

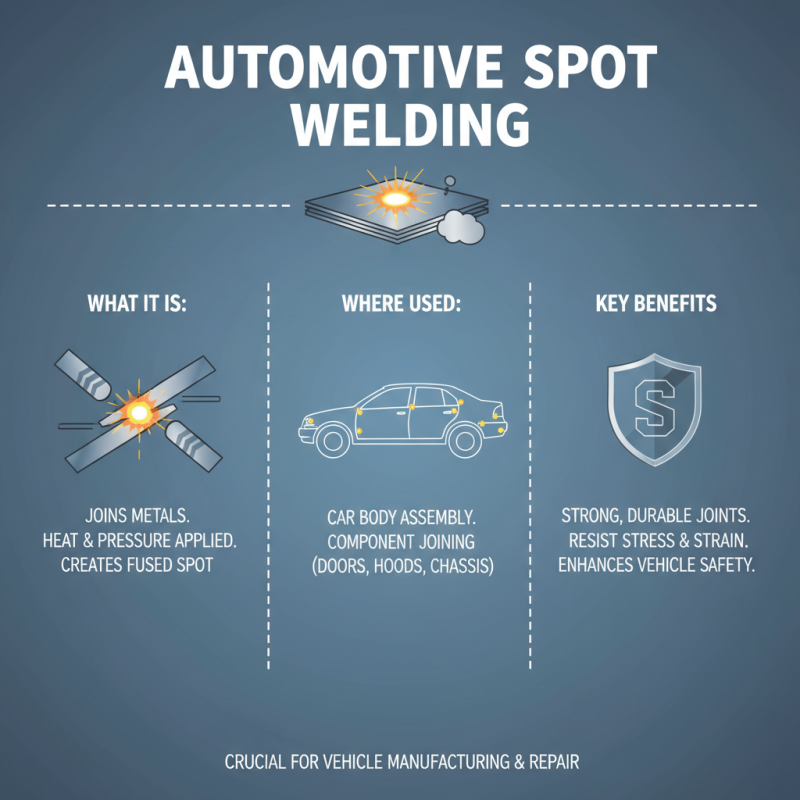

Understanding Automotive Spot Welding and Its Applications

Automotive spot welding is crucial in vehicle manufacturing and repair. This process involves joining two pieces of metal together by applying heat and pressure. The technique is widely used in assembling car bodies and components. It creates strong and durable joints that can withstand stress and strain on the road.

Tips: When considering spot welders, assess your specific needs. Think about the materials you will be working with. Different metals require different settings and techniques. Ensure the model you choose accommodates the thickness of the materials.

Understanding the applications of spot welding can help your decision-making. It is not just limited to bodywork. Spot welding plays a role in electrical connections too. Knowing this can broaden your perspective on its utility.

Tips: Always prioritize safety when welding. Wear appropriate protective gear. Keep your workspace organized. A cluttered area can lead to accidents. Remember, practice makes perfect. Take time to hone your skills with the equipment.

Key Features to Consider When Selecting an Automotive Spot Welder

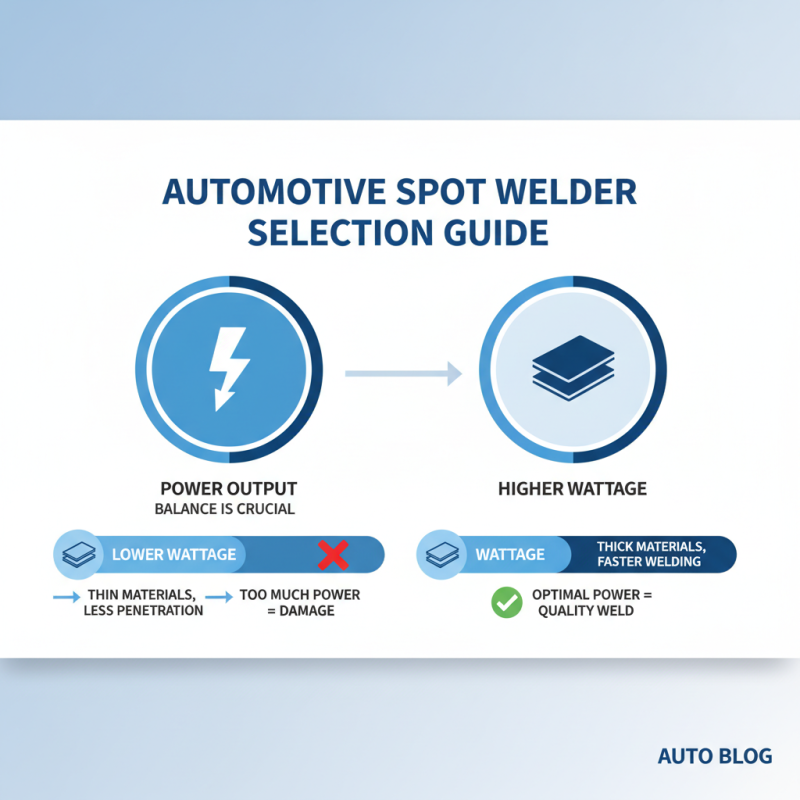

When selecting an automotive spot welder, key features can make a significant difference. Consider the power output. A higher wattage allows for better penetration and faster welding. Yet, too much power might damage thin materials. Balance is crucial.

Look at the control settings. Digital displays offer precision. Analogue dials may seem simpler, but they can lead to inconsistencies. It’s important to have a welder that matches your skill level and project demands. Some welders come with a range of presets. This can help beginners avoid frustration.

Tips: Always check the thickness compatibility. Some welders struggle with extremes. Test on scrap materials before proceeding. Additionally, examine the weight and portability. A lighter model is easier to move but might sacrifice stability. It’s essential to find what's right for your work environment. Adjust your choices based on the projects you most often tackle.

Evaluating Power and Performance Specifications

When selecting an automotive spot welder, power and performance specifications are crucial. Look for welders with adequate amperage for your tasks. Higher amperage provides better penetration and stronger welds. A unit that delivers 3,000 amps is common for most applications. However, what's more important is understanding the materials you will work with.

Different metals require different approaches. For instance, aluminum needs more careful settings compared to steel. Many welders offer adjustable settings. Take the time to experiment with these to find what works best. Test welds can help determine effectiveness. A lower than expected performance can indicate mismatched settings or defective equipment.

It’s essential to consider duty cycle as well. This is the time you can weld before the machine needs a break. A welder with a 60% duty cycle means it runs for six minutes and requires four minutes to cool. This can affect workflow. Never overlook user comfort either. A welder that’s heavy or awkward can lead to fatigue. Balance and weight play significant roles in performance. Understanding these variables will save hours of frustration down the line.

2025 Guide: How to Choose the Best Automotive Spot Welder for Your Needs - Evaluating Power and Performance Specifications

| Model | Power Rating (kW) | Max Weld Thickness (mm) | Duty Cycle (%) | Weight (kg) | Price (USD) |

|---|---|---|---|---|---|

| Model A | 5.0 | 3.0 | 60 | 20 | 1200 |

| Model B | 7.5 | 4.0 | 80 | 25 | 1500 |

| Model C | 6.0 | 3.5 | 75 | 22 | 1350 |

| Model D | 8.0 | 4.5 | 90 | 28 | 1750 |

| Model E | 9.0 | 5.0 | 85 | 30 | 2000 |

Comparing Different Types of Spot Welders for Automotive Use

When comparing different types of automotive spot welders, it's crucial to understand their features.

Resistance spot welders are widely used for car body repairs. They create strong joints by passing electric current through the metal.

However, they can leave marks on the surfaces, which may require additional finishing work.

Inverter spot welders offer a more compact design. They are lightweight and energy efficient. While they work quickly, the learning curve can be steep for new users.

It’s important to practice to achieve consistent results. Additionally, some users find the settings confusing.

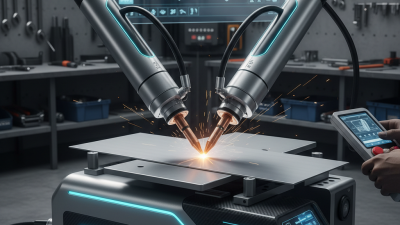

Laser spot welders provide precision. They minimize heat exposure, reducing warping. This type is excellent for delicate work but can be more expensive.

Prospective buyers should weigh the investment against their specific needs. Each type has its advantages and challenges, so careful consideration is key.

Maintenance Tips for Prolonging the Life of Your Spot Welder

Maintaining your spot welder is crucial for its longevity. According to industry reports, regular maintenance can increase the lifespan of spot welders by up to 30%. Simple actions can yield significant results.

One effective tip is to clean the welding tips after every use. Residue buildup can affect performance and result in poor weld quality. A clean environment is essential. Inspect cables and connections regularly. Damaged parts can lead to malfunctions and injuries.

Another useful practice is to check your machine’s calibration. Accurate settings ensure consistent results. Faulty calibrations can lead to unexpected failures. Lastly, always refer to the manufacturer’s guidelines for lubrication. Proper lubrication can enhance efficiency and durability. Neglecting this can lead to decreased performance over time.

Related Posts

-

2025 How to Choose the Right Resistance Spot Welder for Your Needs

-

Unlocking the Future: How Automotive Welding Technologies Are Revolutionizing Vehicle Manufacturing

-

Why You Need a Mini Spot Welding Machine for Your DIY Projects Today

-

How to Choose the Best Resistance Spot Welder for Your Projects in 2025

-

2025 Best Spot Welder Guide for Homeowners and DIY Enthusiasts

-

Why Choose a Resistance Spot Welder for Your Welding Projects

Contact us

Please fill out the enquiry form, and our dedicated team will promptly attend to your request