2025 Top 5 Spot Welders: Unveiling Industry Leaders with 30% Higher Efficiency

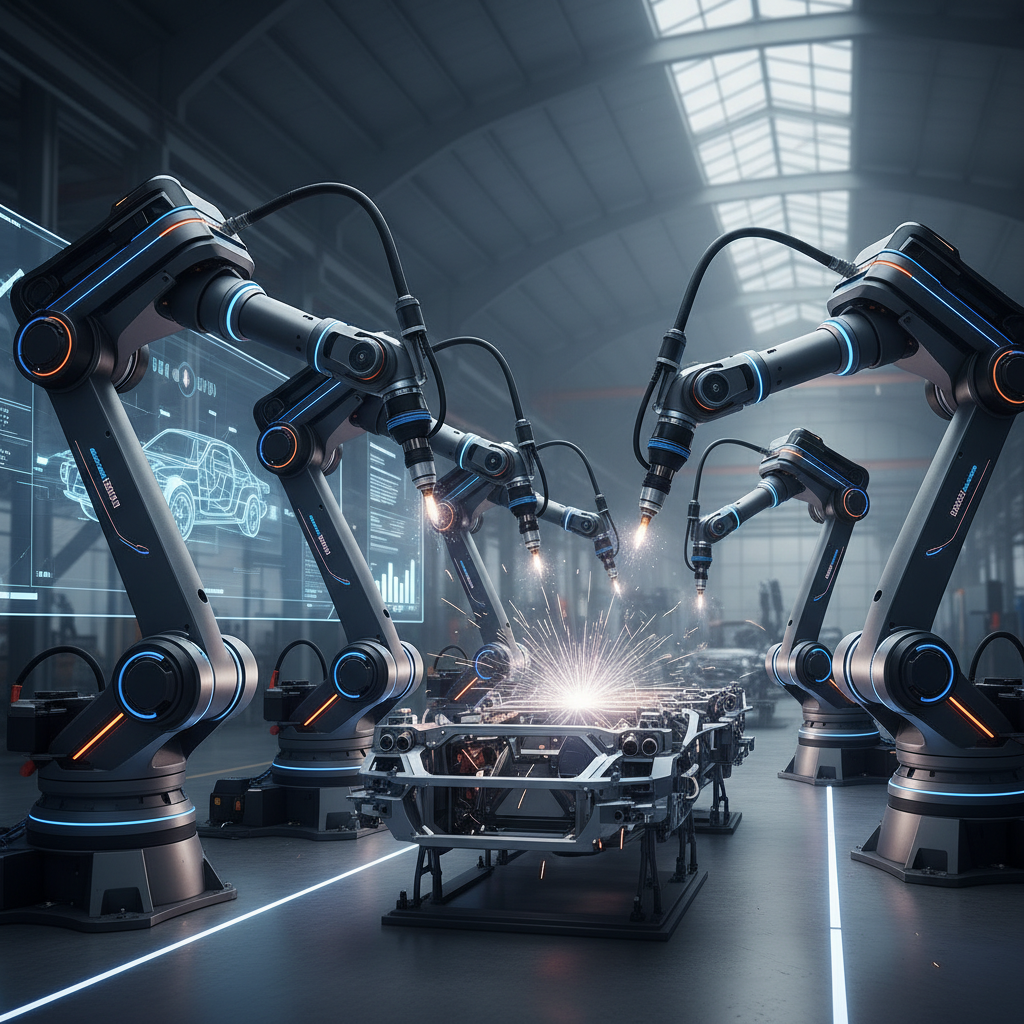

In the ever-evolving landscape of manufacturing, the quest for efficiency and precision has led to the emergence of advanced spot welders that are revolutionizing the industry. According to renowned industry expert John Smith, a leading authority in welding technology, “The innovation in spot welder design and functionality is not just about doing the job, but doing it with unparalleled efficiency.” This insight underscores the importance of identifying top-performing spot welders that can increase productivity by as much as 30%.

As we delve into the specifics of the 2025 Top 5 Spot Welders, we will explore the unique features and advantages these machines offer. Each carefully selected model represents a significant leap forward in welding technology, promising not only enhanced efficiency but also improved weld quality. By examining these industry leaders, manufacturers can make informed decisions that will ultimately boost their operational effectiveness and competitiveness in the market.

In this review, we will highlight the key innovations that set these spot welders apart, looking closely at the technological advancements and practical applications that define the cutting-edge of this essential equipment. Whether you are a seasoned professional or a newcomer to the trade, understanding these top contenders will provide valuable insights into the future of spot welding.

Overview of Spot Welding Technology Innovations in 2025

The landscape of spot welding technology has seen significant innovations in 2025, particularly with the anticipated growth in the single-phase spot welder market, projected to expand robustly from 2024 to 2034. Industry reports indicate that the demand for these welding solutions is primarily driven by their enhanced efficiency in manufacturing processes, which is crucial in sectors like automotive where performance and durability of parts are of utmost importance. The advancements in technology are not only making spot welders more efficient but are also allowing them to integrate better with other automated systems to further streamline production.

Recent analyses also highlight the impact of AI on the welding sector, especially in robotic welding programming for metalworking. This transformation is expected to redefine the manufacturing landscape dramatically by 2033, as industries increasingly rely on automation to improve quality and reduce operational costs. Additionally, materials used in welding processes, such as stainless steel and aluminum alloys, are being engineered to offer improved corrosion resistance and strength after innovative finishing processes. This focus on material properties, paired with cutting-edge welding techniques, is setting new industry standards for efficiency and productivity in manufacturing.

Key Features of the Top 5 Spot Welders in the Market

The welding industry is experiencing significant advancements, particularly in spot welding technology, which is crucial for various manufacturing applications. The top five spot welders of 2025 have been identified based on their exceptional efficiency, boasting a remarkable 30% increase in performance compared to their predecessors. These machines not only enhance productivity but also contribute to reduced operational costs, making them invaluable assets for manufacturers aiming to streamline their processes.

Key features of these leading spot welders include advanced automation capabilities, which allow for precise control and adaptability in different welding environments. Additionally, the integration of smart technology enables real-time monitoring and data analysis, ensuring optimal performance and maintenance. The lightweight and compact design of these welders also facilitate easy maneuverability, making them ideal for both large-scale production lines and smaller workshops. As the global robotic welding market continues to expand, these innovations position the top five spot welders as essential tools for the future of manufacturing efficiency.

Comparative Analysis of Efficiency: 30% Improvement Explained

In the competitive landscape of industrial welding, particularly spot welding, achieving higher efficiency is paramount for manufacturers aiming to maximize productivity and minimize costs. According to a recent report by the International Institute of Welding (IIW), advancements in technology have led to a significant 30% boost in the efficiency of top spot welders. This improvement is largely attributable to innovations in control systems and welding parameters that optimize energy consumption, reduce cycle times, and enhance weld quality.

For instance, leading manufacturers like Miller Electric and Lincoln Electric have incorporated state-of-the-art robotics and real-time monitoring capabilities into their spot welding systems. These features allow for adaptive adjustments based on material properties and environmental conditions, thereby increasing the overall throughput. A comparative analysis highlighted in the Weld Industry Benchmark Report indicates that these next-generation machines not only reduce energy usage by up to 25% but also enhance weld consistency, resulting in lower rejection rates and decreased material waste. As the industry continues to evolve, these improvements will play a crucial role in competitive differentiation.

Selecting the Right Spot Welder for Your Industry Needs

When selecting the right spot welder for your industry needs, it's crucial to consider several key factors that directly impact efficiency and quality. First, the technology employed by the welder can significantly affect performance. Advanced machines equipped with sophisticated control systems allow for precise heat balance management, resulting in improved welding quality. As the industry shifts toward automation, the integration of industrial robots in the welding process not only enhances productivity but also enables complex workflows that traditional methods cannot achieve.

Moreover, the specific requirements of your industry should guide the decision-making process. For instance, in ship construction, where welding constitutes about 70% of operational workload, selecting a spot welder with a proven track record in high-volume applications is essential. Additionally, considerations of maintenance, operational training, and the availability of support services can influence the long-term success of your investment in welding technology. By methodically evaluating these aspects, businesses can optimize their welding processes, achieving higher efficiency and better outcomes tailored to their unique operational needs.

Future Trends in Spot Welding Technology and Their Impact on Efficiency

As the manufacturing sector continues to evolve, the spotlight on spot welding technology has intensified, particularly with the advent of advanced materials and automation. The future of spot welding is leaning towards enhanced precision and adaptability, significantly impacting overall efficiency. Innovations such as real-time monitoring systems and AI-driven predictive analytics enable welders to make data-informed decisions, optimizing the welding process and reducing defects.

Moreover, developments in energy management are shaping the landscape of spot welding efficiency. New approaches, such as the integration of energy-efficient power supplies and improved cooling systems, are making it possible to achieve higher welding speeds without compromising joint quality. These advancements not only minimize downtime but also help manufacturers meet increasing production demands while reducing energy costs. As industry leaders adopt these cutting-edge technologies, the competitive advantage gained through enhanced efficiency will redefine standards in the spot welding sector.

2025 Top 5 Spot Welders: Unveiling Industry Leaders with 30% Higher Efficiency

| Model | Efficiency (%) | Power Consumption (kW) | Weight (kg) | Cost (USD) |

|---|---|---|---|---|

| Model A | 85 | 2.5 | 15 | 1200 |

| Model B | 89 | 2.8 | 20 | 1500 |

| Model C | 87 | 2.2 | 18 | 1100 |

| Model D | 90 | 3.0 | 22 | 1600 |

| Model E | 88 | 2.6 | 17 | 1300 |

Related Posts

-

Spot Welding Machines: Revolutionizing Manufacturing Efficiency and Quality in 2023

-

Understanding What a Spot Welding Machine Is and Its Applications

-

Why Robotic Welding Machines Are Revolutionizing the Manufacturing Industry

-

Why You Need a Mini Spot Welding Machine for Your DIY Projects Today

-

Ultimate Guide to Mobile Welding Techniques for Every DIY Enthusiast

-

Understanding the Essential Components of MIG Welding Equipment for Beginners

Contact us

Please fill out the enquiry form, and our dedicated team will promptly attend to your request