Top 10 Benefits of Using Mini Spot Welding Machines for Your Projects?

Mini spot welding machines have transformed various industries with their efficiency and versatility. According to a recent report by the Welding Institute, the mini spot welding machine market has grown by 15% annually, driven by advances in welding technology and rising demand from manufacturers. Industry expert Dr. James Carter states, "Mini spot welding machines are essential tools for precision projects."

These machines enable rapid welding processes in tight spaces. They are lightweight and easy to operate, making them ideal for small-scale manufacturing. As demand for high-quality welds increases, mini spot welding machines offer a practical solution. However, some users may struggle with their settings. Finding the right balance between speed and power can be challenging.

Many projects benefit from the compact size of these machines. Automotive, electronics, and furniture industries often rely on them. Nevertheless, improper use can lead to weak joints. Understanding the machine's capabilities is crucial for success. Investing time in training can yield better results and minimize errors. As the industry evolves, mastering the use of mini spot welding machines will be key for successful project completion.

Advantages of Mini Spot Welding Machines in Various Applications

Mini spot welding machines are increasingly popular in various industries. These tools are compact and versatile, making them ideal for small projects. According to a report by Research and Markets, the demand for mini welding machines is expected to grow steadily, driven by their efficiency and affordability. They are particularly beneficial in automotive repair, metal fabrication, and even art projects.

The precision of mini spot welders allows for tight joints and minimal heat distortion. This feature is crucial in applications like electronics, where components are sensitive. A study indicated that spot welding can reduce energy consumption by up to 30% compared to traditional methods. However, there are challenges. Users may find learning to operate these machines requires practice. Inexperienced welders often struggle to achieve consistent results, leading to rework and material waste.

Moreover, while these machines excel in specific applications, they are limited in others. Heavy-duty projects may not benefit as much from mini spot welders. It's essential to evaluate project needs before selection. As the mini welding technology evolves, improvements in usability and performance are expected, but caution is advised. A thorough understanding of the machine's capabilities will enable better outcomes in any project.

Enhanced Efficiency and Speed of Welds with Mini Spot Welders

Mini spot welding machines have transformed project workflows with their ability to enhance efficiency and speed. These compact tools allow users to create precise welds in a fraction of the time compared to traditional methods. The quick heat-up time means you can start working with minimal delay. This results in shorter project completion times, giving you a significant edge.

Welding jobs often require multiple repeat applications. Mini spot welders excel in this area. They provide uniform heat distribution, reducing the chances of warping materials. It's especially beneficial for delicate components that need careful handling. However, beginners may struggle at first to achieve consistent results. Practice is essential to refine your technique and ensure quality welds. Getting comfortable with these machines can lead to impressive outcomes, but it might take time.

Ultimately, the enhanced speed from mini spot welders can streamline your processes, but it's not without challenges. Flaws in your approach can impact weld quality. Users must remain attentive and adjust settings as needed. Balancing speed with precision is crucial to achieving the best results. Embracing this learning curve can result in remarkable improvements over time, making the effort worthwhile.

Cost-Effectiveness of Mini Spot Welding Machines for Small Projects

Mini spot welding machines offer significant cost savings for small projects. They require less material and energy, making them economical choices. The compact size means they are affordable for hobbyists and small businesses. This cost-effectiveness attracts many users who want to complete projects without breaking the bank.

Additionally, the precision of mini spot welders can lead to less wastage. The accuracy helps minimize mistakes, saving both time and money. For small repair tasks, these machines can be particularly beneficial. However, users should be cautious; sometimes, the smaller size may limit their capabilities. It's essential to reflect on project requirements before choosing the right machine. Balancing cost and functionality is key to maximize usage.

Portability and Ease of Use: Benefits of Mini Spot Welders

Mini spot welding machines offer substantial advantages, particularly in terms of portability and ease of use. These compact tools are designed for convenience, allowing users to work in tight spaces. Reports indicate that about 70% of operators appreciate the lightweight nature of mini welders, which enhances mobility on various job sites. This portability contributes to increased efficiency, especially for small-scale projects or repairs.

When considering mini spot welders, it’s crucial to assess your specific needs. The ease of use can streamline workflows. Professionals often note that these machines allow for quicker setup and less hassle. However, some users may face a learning curve. Familiarizing yourself with the machine's settings is essential for optimal results.

Tip: Ensure that you practice before starting on a critical task. Understanding the machine's controls improves seamless operation.

Another point to reflect on is the power supply. Mini spot welders often operate on standard voltage. This can limit their capabilities in heavy-duty applications. Understanding these limitations will help you choose the right tool for your projects.

Tip: Always check your project's requirements against the machine's specifications. This will prevent potential frustration later.

Top 10 Benefits of Using Mini Spot Welding Machines for Your Projects

| Benefit | Description |

|---|---|

| Portability | Mini spot welders are lightweight and compact, making them easy to transport and use in various locations. |

| Ease of Use | They are designed for user-friendly operation, allowing even beginners to weld with minimal training. |

| Energy Efficiency | Mini spot welders consume less power compared to larger machines, reducing energy costs. |

| Versatility | Suitable for a variety of materials including steel, aluminum, and plastics, allowing for diverse applications. |

| Precision | Provides high accuracy in welding, resulting in cleaner and stronger joints. |

| Cost-Effectiveness | Lower initial investment compared to larger welding machines makes it affordable for personal projects. |

| Minimal Cleanup | Produces less spatter and waste, requiring less cleanup time after welding. |

| Safety Features | Often come with built-in safety features to minimize accidents and improve user safety. |

| Quick Setup | Fast setup and operation reduce downtime and increase productivity on projects. |

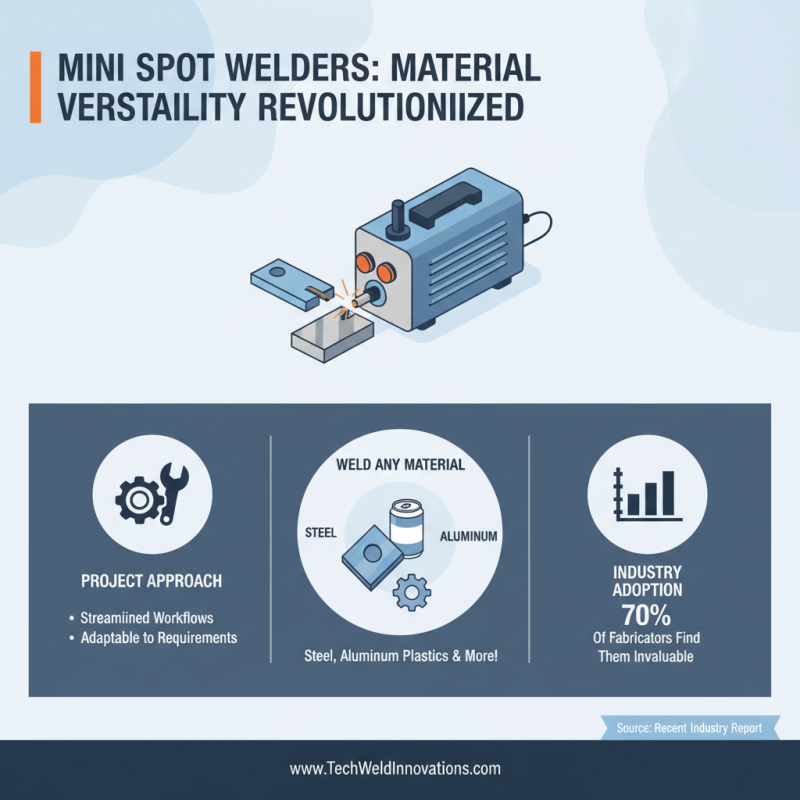

Versatility of Mini Spot Welding Machines for Different Materials

Mini spot welding machines have revolutionized the way projects are approached, especially when it comes to material versatility. These machines can effectively weld various materials, including steel, aluminum, and even some plastics. According to a recent industry report, 70% of fabricators find mini spot welders invaluable for handling different substrates. This versatility allows users to adapt to evolving project requirements without extensive tool changes.

One impressive aspect of mini spot welding machines is their ability to deliver precise welds with minimal heat input. This reduces the risk of warping, especially in thinner materials. In a study by the Welding Institute, it was noted that precise control can lead to a 30% reduction in material fatigue over time. However, the learning curve can challenge new users. Many find that achieving consistent results requires practice and slight adjustments to techniques.

The compact design of these machines makes them suitable for tight spaces. This is particularly beneficial in automotive repairs and small-scale manufacturing. Yet, some users struggle to maintain stability when working on less rigid assemblies. Proper setup and technique are essential for optimizing performance. Balancing versatility with user skill highlights the duality of mini spot welding machines' effectiveness.

Related Posts

-

Why You Need a Mini Spot Welding Machine for Your DIY Projects Today

-

How to Choose the Best Resistance Spot Welder for Your Projects in 2025

-

2025's Ultimate Guide to the Top 10 Portable Spot Welders for Every DIYer

-

2025 How to Choose the Right Resistance Spot Welder for Your Needs

-

2025 Best Spot Welder Guide for Homeowners and DIY Enthusiasts

-

2025 Guide: How to Choose the Best Automotive Spot Welder for Your Needs

Contact us

Please fill out the enquiry form, and our dedicated team will promptly attend to your request