Best Mini Spot Welding Machine for Efficient and Precise Metal Joining

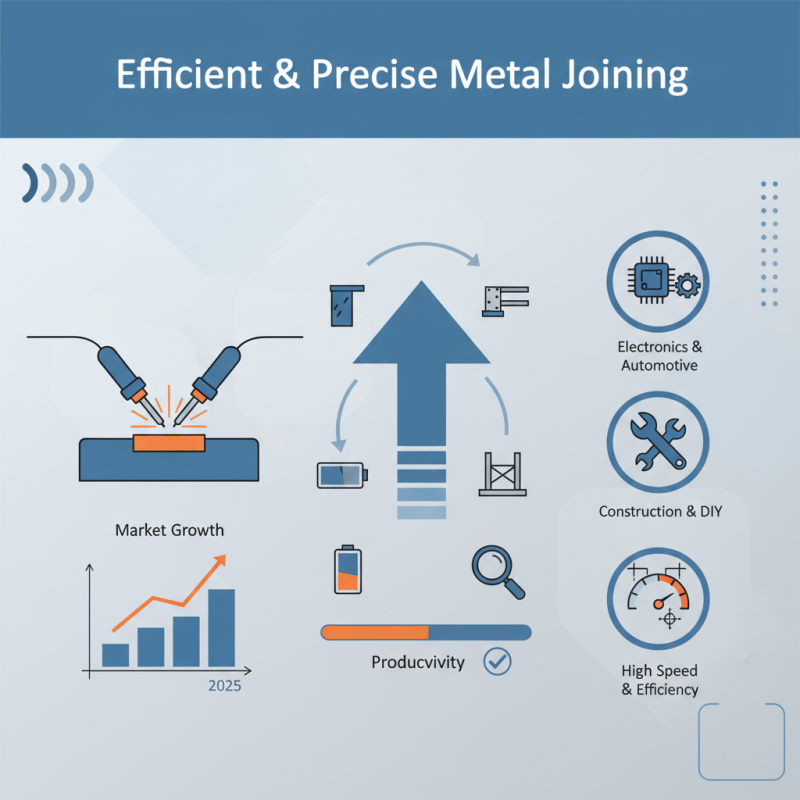

In recent years, the demand for efficient and precise metal joining techniques has surged, driven by advancements in various industries such as automotive manufacturing, electronics, and construction. Among these techniques, the mini spot welding machine has gained significant popularity for its ability to deliver high-quality welds with minimal energy consumption. According to a report by MarketsandMarkets, the global spot welding equipment market is projected to reach USD 4.1 billion by 2025, highlighting the growing reliance on this technology for robust metal fabrication.

The mini spot welding machine offers several advantages, including portability, ease of use, and adaptability for small-scale projects. These machines are well-suited for various applications, from delicate electronics assembly to lightweight metal structures. As industries increasingly focus on efficiency and precision, mini spot welders are becoming invaluable tools for both professional welders and DIY enthusiasts alike. A recent survey conducted by the International Institute of Welding shows that over 70% of welding professionals value the speed and accuracy provided by compact welding solutions, further emphasizing the essential role of mini spot welding machines in modern fabrication processes.

With the continuous evolution of welding technology, investing in a reliable mini spot welding machine can significantly enhance productivity while ensuring high-quality welding results. As more businesses recognize the potential of these machines, understanding their features and capabilities is essential for achieving optimal performance in metal joining tasks.

Understanding Mini Spot Welding Machines: Key Features and Benefits

Mini spot welding machines have gained popularity in various industries due to their compact size and remarkable efficiency. These machines are designed for precise metal joining, making them ideal for tasks that require high accuracy in tight spaces. One key feature of mini spot welders is their portability, enabling users to operate them in diverse environments, from workshops to field applications. Additionally, their ease of operation allows both seasoned professionals and beginners to achieve consistent weld quality without extensive training.

Another significant benefit of mini spot welding machines is their energy efficiency. Many models incorporate advanced technology that reduces power consumption while maintaining strong welding capabilities. This aspect not only lowers operational costs but also minimizes the environmental impact associated with metal joining processes. Furthermore, mini spot welders often feature adjustable settings for welding time and pressure, providing users with the flexibility to tailor their approach based on the specific materials being joined. This adaptability enhances the quality of the welds achieved, resulting in stronger, more durable connections.

Types of Mini Spot Welding Machines: A Comprehensive Overview

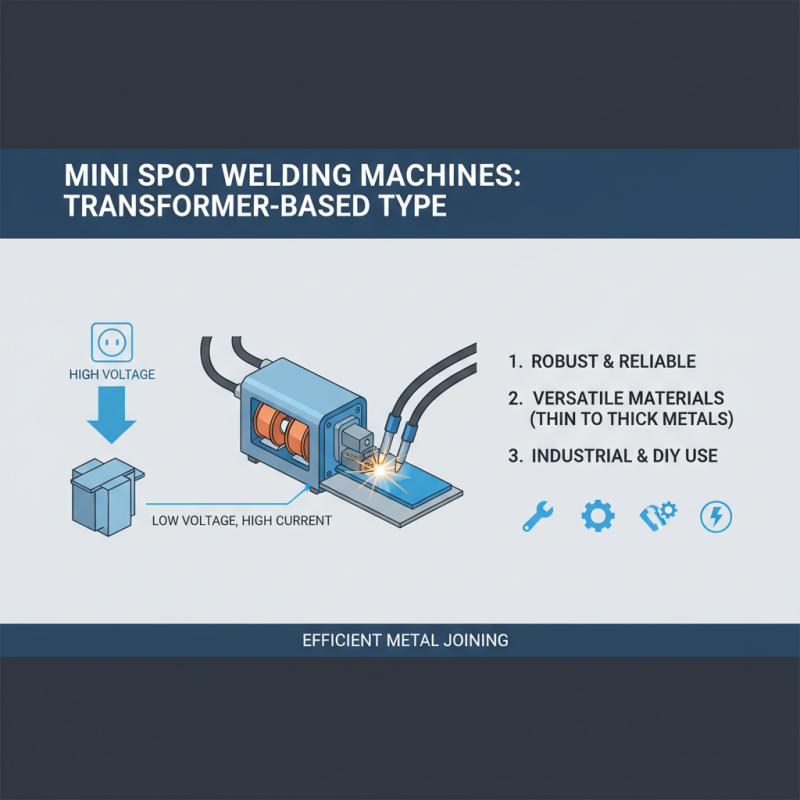

Mini spot welding machines come in a variety of types, each designed to meet specific needs in metal joining applications. One of the most common types is the transformer-based mini spot welder, which utilizes a transformer to convert high voltage into low voltage, allowing for efficient welding of metals. This type is favored for its robustness and ability to handle various materials, from thin sheets to thicker sections, making it versatile in both industrial and DIY environments.

Another popular option is the inverter mini spot welder, known for its compact size and portability. Inverter technology allows for precise control over the welding process, making it suitable for delicate projects that require fine adjustments. Additionally, these machines often have features like adjustable welding time and current, enabling users to customize the process according to the material being welded. With advancements in technology, inverter mini spot welders offer improved energy efficiency and can handle a broader range of welding applications, from automotive repairs to jewelry making.

Factors to Consider When Choosing a Mini Spot Welding Machine

When choosing a mini spot welding machine, several critical factors should be evaluated to ensure efficient and precise metal joining. First, consider the machine's power output, typically measured in volts and amps. Reports indicate that a machine with at least 120 amps can handle most lightweight materials effectively, while heavier gauges may require units delivering 250 amps or more. Additionally, check the duty cycle, which reflects how long the machine can operate at full power without overheating. A duty cycle of 60% is recommended for home users to ensure reliability during extended tasks.

Another essential aspect is the machine's portability and design. Given that mini spot welders are often used in tight spaces, a compact, lightweight design can greatly enhance usability. Look for features such as ergonomic handles and convenient controls that allow for easy operation. The ease of maintenance is also paramount; machines with easily accessible parts usually result in lower downtime and improved performance.

Tips: Always review the welding capabilities of the machine, especially the thickness of the materials it can join. For instance, a good mini spot welder should be able to effectively weld materials up to 1.5mm thick. Additionally, consider investing in a machine with advanced safety features, such as automatic shut-off or thermal overload protection, to ensure safe and efficient operation during use.

Mini Spot Welding Machine Efficiency Comparison

Top Models of Mini Spot Welding Machines on the Market

Mini spot welding machines have gained popularity in various industries for their efficiency and precision in metal joining. As the demand for compact and reliable welding solutions increases, several top models have emerged in the market. According to a recent industry report, the global mini spot welding machine market is projected to grow at a CAGR of over 6% from 2023 to 2030, driven by advancements in welding technology and rising applications in automotive manufacturing and electronics assembly.

Many models stand out for their performance and user-friendly design. For instance, several machines feature adjustable power settings that allow users to tailor their welding strength based on the thickness of the materials being joined. This versatility is crucial for improving the integrity of welds in different applications. Furthermore, energy-efficient systems reduce operational costs while delivering high-quality results. In fact, studies have shown that using modern mini spot welders can reduce energy consumption by up to 30% compared to conventional systems.

Tips: When selecting a mini spot welding machine, consider the range of materials you will be working with and opt for a model that offers flexibility in power settings. Additionally, understand the machine's duty cycle, as this determines how long you can operate it continuously without overheating, ensuring consistent performance during prolonged tasks. Investing in a reliable machine will not only enhance productivity but also improve the overall quality of your metal joining projects.

Best Mini Spot Welding Machine for Efficient and Precise Metal Joining

| Model | Max Output (Amps) | Welding Thickness (mm) | Weight (kg) | Price (USD) |

|---|---|---|---|---|

| Model A | 120 | 1.0 | 3.5 | 150 |

| Model B | 150 | 1.2 | 4.0 | 200 |

| Model C | 100 | 0.8 | 3.0 | 120 |

| Model D | 200 | 1.5 | 5.5 | 250 |

Tips for Efficient Usage and Maintenance of Mini Spot Welders

When using a mini spot welding machine, efficient usage hinges on understanding its operational parameters. Start by selecting the appropriate voltage and current settings based on the thickness and type of the metals you're working with. This adjustment is crucial as it not only ensures strong welds but also prevents metal distortion or damage. Properly positioning the electrodes is equally important; make sure they are clean and aligned to achieve optimal contact with the materials being joined. Assess your workpieces before starting to identify any imperfections that may interfere with the weld quality.

Maintenance is vital for the longevity and reliability of your mini spot welder. Regularly inspect the condition of the electrodes and replace them when you notice significant wear or pitting, as worn electrodes can lead to inefficient welding and increased energy consumption. Additionally, keep the machine clean and free of dust and debris; a cluttered workspace can hinder performance and pose safety risks. Lubricate moving parts as recommended by the manufacturer to ensure smooth operation. By prioritizing these practices, you can maximize the effectiveness of your mini spot welding machine, resulting in precise and robust metal joints.

Related Posts

-

Unveiling the Best Spot Welder for Home Projects with Essential Insights and Expert Tips

-

2025 How to Choose the Right Resistance Spot Welder for Your Projects

-

2025 Top 5 Spot Welders: Unveiling Industry Leaders with 30% Higher Efficiency

-

Spot Welding Machines: Revolutionizing Manufacturing Efficiency and Quality in 2023

-

Top Tips for Choosing the Best MIG Welder in 2025 for Your Projects

-

2025 Top 5 Best Spot Welders: Unmatched Performance & Efficiency Ratings

Contact us

Please fill out the enquiry form, and our dedicated team will promptly attend to your request