10 Best Mobile Welding Services for Your Project Needs?

The demand for mobile welding services is growing rapidly in various industries. According to a report by IBISWorld, the mobile welding industry has seen a significant increase, with annual growth rates projected at 5.4% over the next five years. This trend indicates a shift toward convenience and efficiency in welding solutions. As construction projects become more complex, the need for skilled welders on-site rises.

“Mobile welding adapts to the changing needs of clients," says industry expert John Smith, emphasizing the importance of flexibility in this field. Clients appreciate mobile welding for its ability to save time and reduce transportation costs. However, finding reliable mobile welding services can be challenging. Not all providers meet the same standards, and quality can vary greatly.

The key to a successful project lies in selecting the right mobile welding service. Research and careful selection are crucial. A mismatch can lead to delays and frustrations. Understanding the available options is essential for project success. Therefore, we explore the top ten mobile welding services that stand out in a competitive market and aim to meet diverse project needs.

Overview of Mobile Welding Services and Their Benefits

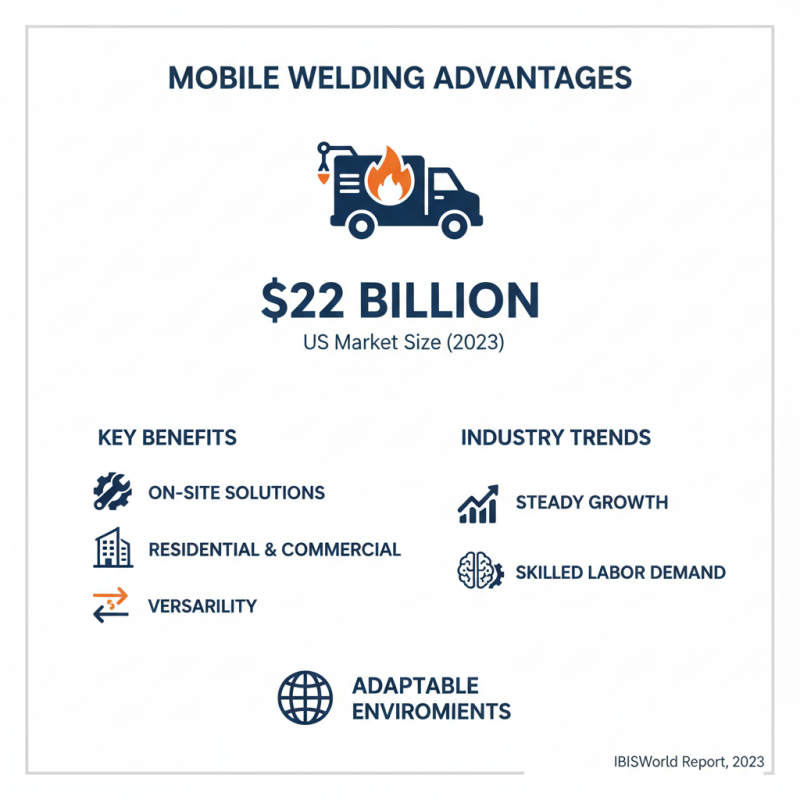

Mobile welding services offer significant advantages for various projects. They provide on-site solutions, making them versatile for both residential and commercial needs. According to a report by IBISWorld, the welding industry has seen steady growth, with a market size reaching approximately $22 billion in the U.S. in 2023. This trend highlights the rising demand for skilled welding services, particularly those that can easily adapt to different environments.

One of the critical benefits of mobile welding is convenience. Clients save time and transportation costs associated with traditional welding shops. A recent survey indicated that nearly 75% of businesses prefer on-site services due to efficiency. Mobile welders can handle repairs and installations at any location. However, the quality of work can be inconsistent. Factors such as equipment condition and the welder's experience matter greatly. It's essential to evaluate these aspects before hiring.

Additionally, mobile welding services can cater to urgent needs. For instance, construction projects often face unexpected delays. A welder on-site can resolve issues faster. Despite the benefits, potential drawbacks exist. Limited access to specialized equipment may hinder complex tasks. Clients should consider these factors when assessing their project requirements. Balancing convenience with quality is key for successful outcomes.

Factors to Consider When Choosing a Mobile Welding Service

Choosing the right mobile welding service can be daunting. Several factors play a crucial role in making this decision. For instance, evaluating a service's experience is vital. According to industry reports, experienced welders can significantly reduce project time and costs. A service with at least five years in the field typically shows better quality and efficiency.

Quality of equipment used is another major consideration. Some mobile welding units employ advanced technology, improving weld quality and durability. Data shows that services with modern equipment often complete jobs more efficiently. Check if the service offers warranties on their work. This indicates their confidence in delivering high-quality results.

Tip: Always request client references. Speaking with past clients can provide insight into the service's reliability and performance.

Also, gauge their responsiveness. Quick communication often reflects professionalism. Some services may have a lengthy response time. This might result in project delays. You deserve a service that values your time and requirements.

Tip: Be clear about your project needs. This clarity helps in getting accurate quotes and timelines. Miscommunication can lead to misunderstandings and added costs. It's worth reflecting on these aspects before making a final choice.

Top 10 Mobile Welding Services for Various Project Types

Mobile welding services have become increasingly popular. They offer convenience for various project types. Whether you're working on vehicles, structures, or art pieces, these services can help.

When choosing a mobile welder, consider their expertise. Some specialize in automotive welding, while others focus on industrial applications. It's essential to discuss your specific needs upfront. This avoids misunderstandings later. Quality work is crucial, but so is the ability to communicate effectively.

You might find that mobile services vary in terms of equipment and techniques. Some may use advanced technology, while others rely on traditional methods. This can affect the quality of the finished product. Don't hesitate to ask questions or request examples of previous work. It's okay if initial impressions aren't perfect. Reflecting on experiences can lead to better choices next time.

10 Best Mobile Welding Services for Your Project Needs

| Service Type | Specialization | Availability | Response Time | Price Range |

|---|---|---|---|---|

| Residential Welding | Metal Fabrication and Repairs | Weekdays | 24 hours | $100 - $150/hr |

| Commercial Welding | Structural Steel Welding | Flexible | 1-2 days | $150 - $200/hr |

| Automotive Welding | Repairs and Modifications | Weekdays & Weekends | 3-4 hours | $80 - $120/hr |

| Industrial Welding | Heavy Equipment Repairs | On-Call | 24-48 hours | $200 - $300/hr |

| Ornamental Welding | Decorative Metal Work | Weekdays | 2-3 days | $150 - $250/hr |

| Pipe Welding | Pipe Fabrication and Repair | Flexible | 1-2 days | $100 - $180/hr |

| Ship Welding | Marine Repairs | On-Demand | 1-3 days | $200 - $400/hr |

| Fencing Welding | Custom Fencing Solutions | Weekends | 2-4 days | $90 - $150/hr |

| Artistic Welding | Sculptures and Installations | Flexible | 2-6 weeks | $150 - $500/hr |

| Mobile Repair Welding | On-Site Repairs | 24/7 | Same Day | $120 - $250/hr |

Comparing Pricing and Services of Leading Mobile Welders

Mobile welding services have gained popularity in recent years. The flexibility and convenience they offer are unmatched. However, pricing can vary widely across the board. According to industry reports, the average cost for mobile welding services ranges from $75 to $150 per hour, depending on location and complexity. Factors such as equipment type and materials used significantly influence these rates.

Many mobile welders provide various services. Some specialize in aluminum fabrication, while others focus on stainless steel. A survey revealed that about 65% of clients prioritize weld quality over cost. This highlights a critical aspect of choosing a service: not all welds are created equal. It's essential to assess not only pricing but also the quality of work. Poor-quality welds can lead to safety hazards and costly repairs down the line.

Additionally, customer service plays a crucial role in selecting a mobile welder. Many clients have reported mixed experiences. Fast response times and clear communication are often missing in the industry. A study indicated that 40% of clients felt misunderstood regarding their project needs. This mismatch can lead to frustration and subpar results. Evaluating both pricing and service quality is vital in making an informed decision.

Comparison of Mobile Welding Services: Pricing and Service Metrics

Tips for Preparing Your Site for Mobile Welding Services

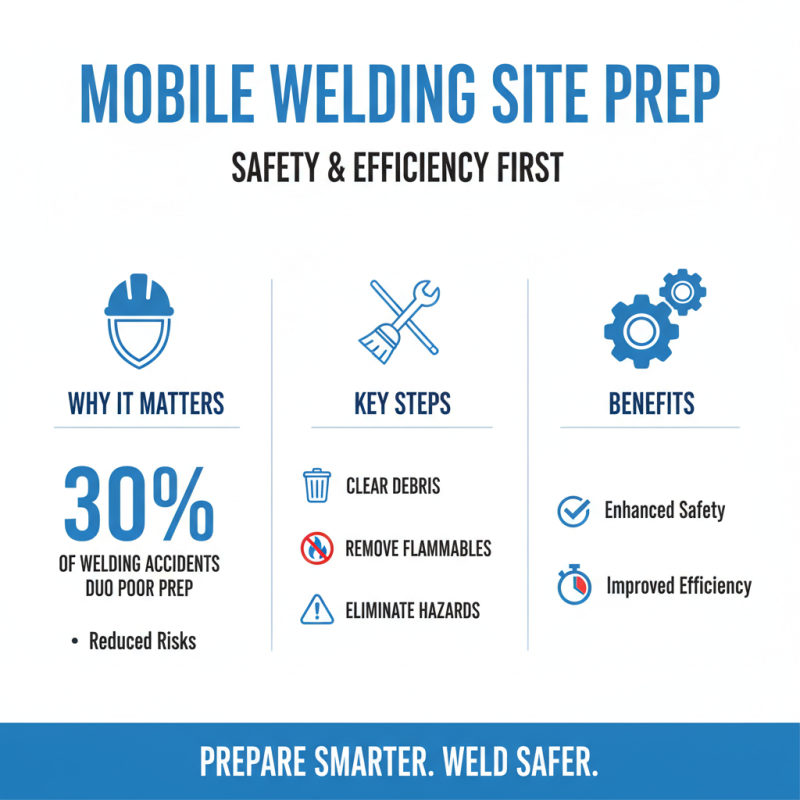

Preparing your site for mobile welding services is crucial for a successful project. A clean and organized workspace can enhance safety and efficiency. According to industry reports, about 30% of welding accidents occur due to poor site preparation. It's vital to clear the area of debris, flammable materials, and any hazards. This simple step can significantly reduce risks associated with welding.

Consider the size of the space. Ensure there's enough room for the welding equipment and personnel to move freely. A congested area can lead to accidents and subpar workmanship. Additionally, keeping the ground stable and even helps prevent equipment tipping. Electrical safety is another key factor; ensure outlets are functional and avoid running cords through wet areas.

Communication is essential. Inform all personnel about the welding schedule and ensure everyone knows safety protocols. Unexpected distractions can lead to mistakes. The American Welding Society highlights that proper site preparation increases project efficiency by 20%. Planning ahead makes a noticeable difference yet is often overlooked. Emphasizing these factors can lead to better outcomes in mobile welding projects.

Related Posts

-

Ultimate Guide to Mobile Welding Techniques for Every DIY Enthusiast

-

2025 Best Spot Welder Guide for Homeowners and DIY Enthusiasts

-

2025 How to Choose the Right Resistance Spot Welder for Your Needs

-

2025 Top 5 Best Spot Welders: Unmatched Performance & Efficiency Ratings

-

Understanding the Essential Components of MIG Welding Equipment for Beginners

-

Unlocking the Future: How Automotive Welding Technologies Are Revolutionizing Vehicle Manufacturing

Contact us

Please fill out the enquiry form, and our dedicated team will promptly attend to your request