2025 How to Choose the Right Resistance Spot Welder for Your Projects

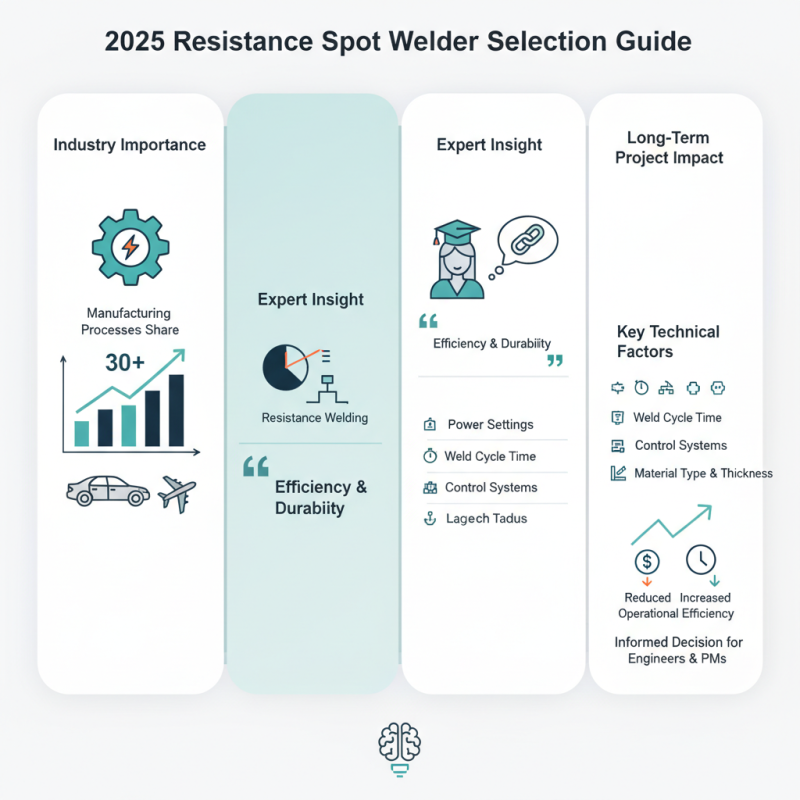

In the competitive landscape of manufacturing and metal fabrication, the choice of equipment can significantly impact productivity and product quality. A critical piece of machinery in this domain is the resistance spot welder, which is essential for creating strong, reliable joins in metal components. According to the 2022 Welding Industry Report by the American Welding Society, resistance welding accounts for over 30% of all welding processes used in manufacturing today, highlighting its importance in various sectors including automotive and aerospace.

Expert insights from Dr. Jane Smith, a renowned figure in the welding technology field, emphasize the significance of selecting the right resistance spot welder for specific applications. She states, “Choosing the right resistance spot welder not only enhances the efficiency of the welding process but also ensures the longevity and durability of the welded joints.” This underscores the necessity of understanding not just the technical specifications but the end-use requirements of projects.

As we move towards 2025, the technological advancements in welding techniques necessitate a well-informed approach to selecting the appropriate resistance spot welder. With so many options available, evaluating features such as power settings, weld cycle time, and control systems becomes paramount. Making the right choice can lead to increased operational efficiency and reduced costs in the long run, making it a crucial decision for engineers and project managers alike.

Understanding the Basics of Resistance Spot Welding Technology

Resistance spot welding is a widely used technique in manufacturing and metalworking, primarily due to its efficiency and simplicity. At its core, the process involves the application of electrical current to join two or more metal pieces together at specific points, known as "spots". The technique relies on the principles of resistance heating, where the electrical resistance of the materials generates heat at the contact point, enabling the formation of a weld. Understanding these fundamentals is crucial for anyone looking to select the right equipment for their projects.

When choosing a resistance spot welder, it's essential to consider various factors that affect performance. These include the thickness and type of materials being welded, the desired strength of the joints, and the production rate. Each project may have unique requirements, so understanding the capabilities of the welders, such as their amperage and cycle time, is vital. Additionally, it's important to recognize the significance of proper electrode selection and maintenance since these components greatly impact the quality of the welds produced.

By grasping the basic concepts of resistance spot welding technology, you can make informed choices that enhance your welding projects' efficiency and effectiveness.

Identifying the Key Factors for Selecting the Right Spot Welder

When selecting the right resistance spot welder for your projects, it's essential to consider several key factors. First and foremost, the thickness of the materials you intend to work with plays a significant role. Spot welders are designed to handle specific material thicknesses, so understanding the range your projects fall into will help narrow down your options. Additionally, consider the types of materials you'll be welding. Different welders have varying capabilities with metals such as mild steel, stainless steel, or aluminum, making it crucial to choose a model that aligns with your material needs.

Another factor to assess is the power output of the welder. A higher power output typically means deeper penetration and faster welding times, which can improve efficiency for larger projects. On the other hand, if you’re working on intricate designs or thinner materials, a welder with adjustable settings could be more beneficial. Don't forget to evaluate the portability and size of the device as well, especially if you plan to work in different locations.

Tips: Always review user manuals and specifications beforehand to ensure compatibility with your specific project requirements. Additionally, consider joining online forums or communities where you can gather real-user experiences and feedback on different models. Lastly, investing in a welder that offers easy maintenance can save you time and money in the long run.

Evaluating the Power and Capacity Requirements for Your Projects

When choosing the right resistance spot welder for your projects, understanding the power and capacity requirements is crucial. The power output of a spot welder is typically measured in kilowatts, which directly impacts its ability to weld different materials and thicknesses. For lighter gauge metals, a lower power output may suffice, but as the thickness and material type increase, so too does the need for a welder capable of delivering higher amperage and energy per weld cycle. Assessing the specific requirements of your project will guide you in selecting a machine that can perform effectively without sacrificing weld quality.

In addition to power, consider the capacity of the welder which encompasses the size and weight of the materials you intend to work with. The capacity also refers to the welder’s cycle time and its duty cycle, which determines how long the machine can operate continuously before cooling down is needed. If your projects involve heavier materials or require prolonged welding runs, opting for a welder with a higher duty cycle will ensure efficiency and reduce downtime. Balancing these factors will equip you with the right resistance spot welder tailored to your specific applications and lead to successful welding outcomes.

Comparing the Features and Benefits of Different Spot Welder Models

When it comes to selecting the right resistance spot welder for your projects, understanding the various features and benefits of different models is crucial. One key aspect to consider is the welding capacity, which typically ranges from lightweight models for simple tasks to heavy-duty machines suitable for industrial applications. The power output is another significant factor, as higher wattage can facilitate faster and more efficient welding, making it essential for larger projects or repeated use.

Additional features to evaluate include the control mechanisms available on the welder, such as digital displays and programmable settings that allow for precise control over the welding process. The versatility of the welder, including the ability to handle different materials and thicknesses, is also vital. Some models offer specialized attachments or tips that enhance their functionality for specific types of jobs. Evaluating the overall build quality and ease of use will ensure that the welder not only meets your project requirements but also provides a reliable and user-friendly experience.

Assessing the Budget and Cost of Ownership for Your Resistance Welder

When considering a resistance spot welder for your projects, assessing the budget and cost of ownership is crucial. Start by determining your initial investment capability. Resistance welders come in a range of prices, influenced by features such as power, control options, and automation levels. It's important to weigh the upfront cost against the potential benefits. Remember, a more expensive welder may offer enhanced efficiency and longevity, which could save you money in the long run.

Next, consider the cost of maintenance and parts replacement over time. A welder that appears more affordable upfront may incur higher operational costs if it has a history of frequent repairs or requires expensive components. Look into the availability of spare parts and the manufacturer's service reputation. Calculate the total cost of ownership, factoring in consumables like electrodes, and downtime for repairs, to get a clearer financial picture.

Related Posts

-

7 Key Benefits of Robotic Welders: Transforming Manufacturing Efficiency in 2023

-

Ultimate Guide to Starting Your Own Mobile Welding Business in 2023

-

Revolutionizing Industrial Manufacturing: The Future of Seam Welding Machines in Modern Applications

-

Spot Welding Machines: Revolutionizing Manufacturing Efficiency and Quality in 2023

-

2025's Ultimate Guide to the Top 10 Portable Spot Welders for Every DIYer

-

2025 Top 5 Best Spot Welders: Unmatched Performance & Efficiency Ratings

Contact us

Please fill out the enquiry form, and our dedicated team will promptly attend to your request