10 Essential Tips for Welding Metal Like a Pro: Techniques and Safety

In the realm of manufacturing and construction, welding metal is a critical skill that underpins the integrity and longevity of countless structures and products. According to the Fabricators & Manufacturers Association (FMA), over 50% of all fabrication companies report that skilled welding professionals are in short supply, highlighting the growing demand for expert welders in the industry. To become proficient in welding metal requires not only hands-on experience but also an understanding of essential techniques and safety protocols that can make all the difference between a mediocre weld and a professional one.

Renowned welding expert, Dr. John Anderson, states, "Mastering the art of welding metal is not just about joining two pieces together; it’s about understanding the science behind it to ensure a strong and durable bond." This encapsulates the essence of proficient welding, which involves a blend of technical know-how and adherence to safety practices. With the right guidance, such as the ten essential tips outlined in this guide, aspiring welders can elevate their skills and approach welding metal with confidence, ensuring that they are not only efficient but also safe in their craft.

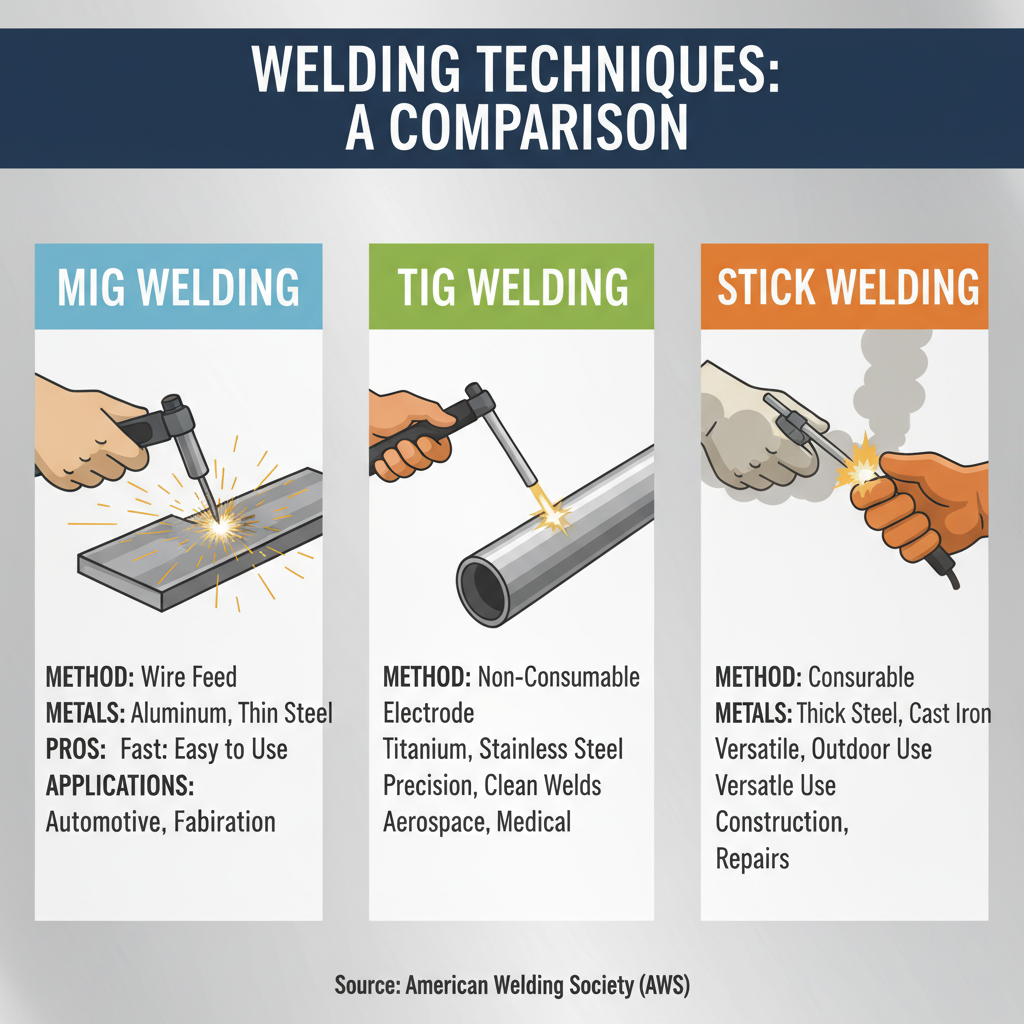

Understanding Different Welding Techniques for Various Metals

Welding is a skilled trade that requires an understanding of different techniques suited for various metals. Common methods such as MIG, TIG, and Stick welding offer unique advantages depending on the material and application. For instance, according to the American Welding Society (AWS), MIG welding is popular for its speed and ease of use, particularly when working with aluminum and thin sheets of steel. In contrast, TIG welding provides superior precision and is ideal for non-ferrous metals like titanium and stainless steel, ensuring clean and strong welds.

To master welding, it’s essential to adapt your technique to the metal you are working with. One tip is to maintain the right welding speed; too fast can lead to weak joints, while too slow can cause burn-through. Additionally, always ensure that your workpieces are clean and free from contaminants, as the presence of rust or oil can seriously compromise the integrity of the weld.

As you develop your skills, always prioritize safety. Using proper gear such as welding helmets and gloves will protect you from harmful UV radiation and heat. Furthermore, a well-ventilated workspace is critical to avoid inhaling toxic fumes, with reports indicating that adequate ventilation can reduce respiratory hazards by up to 75%. By understanding the nuances of various welding techniques and adhering to safety practices, you can elevate your welding proficiency to a professional level.

Essential Safety Gear Every Welder Should Use to Prevent Injuries

When it comes to welding, safety should always be the foremost priority. According to the Occupational Safety and Health Administration (OSHA), over 50,000 workers are injured annually due to welding-related incidents, making it crucial for welders to adopt proper safety measures. The essential safety gear every welder should use includes welding helmets, gloves, protective clothing, and respiratory protection. A welding helmet with a proper filter shade is paramount for protecting the eyes and face from harmful UV rays and sparks.

In addition to personal protective equipment (PPE), it's also vital to ensure that your workspace is safe. Welding can produce harmful fumes, which is where a high-quality respirator comes into play. The American Welding Society (AWS) emphasizes the importance of using adequate ventilation systems to minimize exposure to hazardous fumes and gases.

Moreover, maintaining a clutter-free workspace can significantly reduce the risk of accidents. Always remember to check for potential fire hazards and ensure that flammable materials are stored away from your welding area. By combining the right safety gear with a vigilant approach to your environment, you set a strong foundation for welders, whether novice or experienced, to work more confidently and efficiently.

Pre-Welding Preparation: Ensuring a Clean and Safe Workspace

Before diving into the welding process, it's crucial to prepare your workspace to ensure both safety and effectiveness. A clean and organized area minimizes the risks associated with welding, such as fire hazards and accidents. Begin by removing any flammable materials from the vicinity. Ensure that your workspace is well-ventilated to disperse any harmful fumes that might be generated during the welding process. A tidy setup not only enhances safety but also allows for efficient movement as you work.

Tip: Always wear appropriate personal protective equipment (PPE) such as gloves, goggles, and a welding helmet to shield yourself from sparks and UV rays.

Lastly, check your tools and equipment before starting the project. Inspect cables for damage and ensure that your welding machine is functioning properly. Having everything in optimal condition will help you avoid interruptions and will contribute to a smoother welding experience.

Tip: Create a checklist for pre-welding tasks, including equipment checks and safety measures, to ensure nothing is overlooked. This simple step can significantly enhance your preparedness and increase your chances of success in your welding projects.

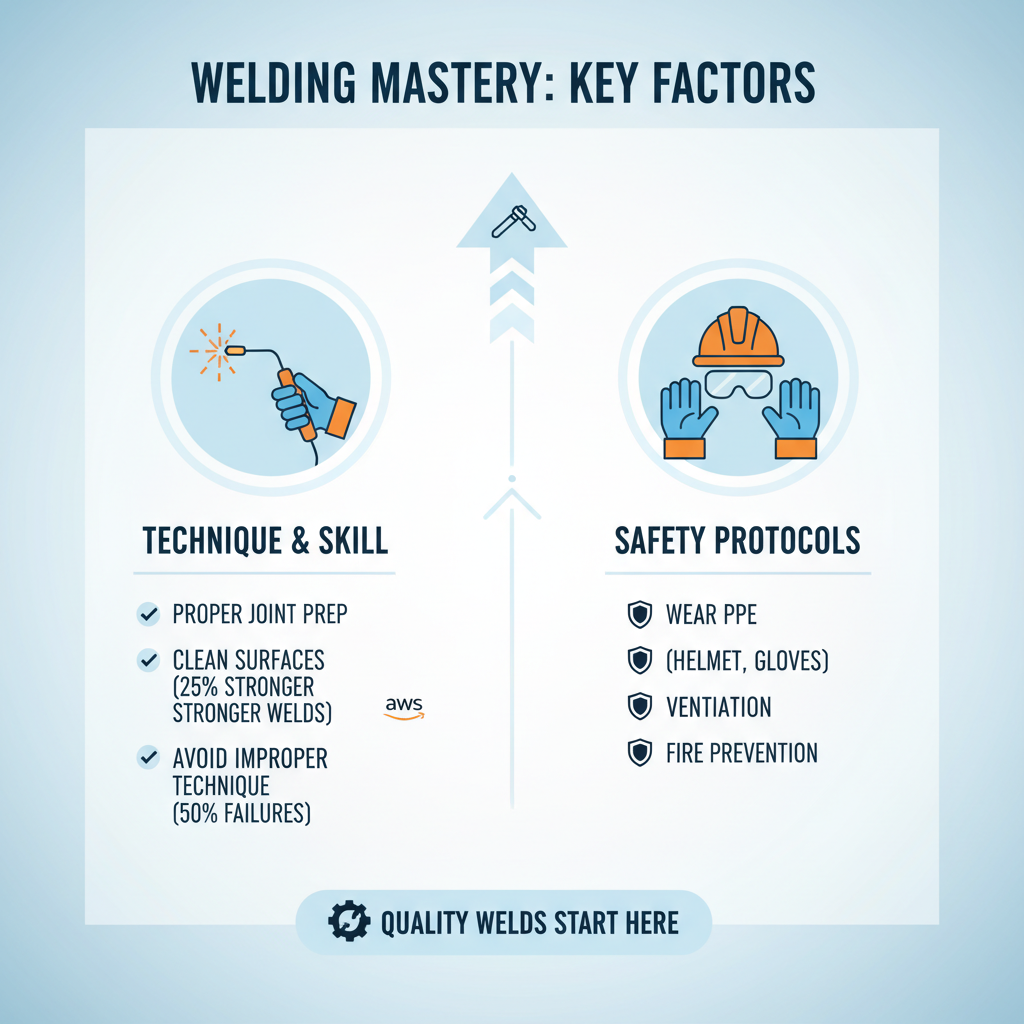

Mastering the Welding Process: Tips for Better Technique and Precision

Mastering the welding process requires a combination of skill, technique, and adherence to safety protocols. According to the American Welding Society (AWS), over 50% of welding failures can be attributed to improper technique. For example, ensuring proper joint preparation and cleanliness can greatly enhance the structural integrity of the weld. A study published in the Journal of Materials Science found that welds with a clean surface prep exhibited a 25% increase in tensile strength compared to those with contaminants. This emphasizes the importance of proper technique and preparation before starting any welding project.

Additionally, achieving precision in welding is crucial for both aesthetic and functional results. The National Center for Construction Education and Research (NCCER) notes that precision in welding can reduce the need for costly repairs and rework, saving companies an average of 10% to 20% on project budgets. Utilizing techniques such as maintaining consistent amperage and travel speed can help welders achieve more accurate and aesthetically pleasing results. As the industry moves towards automation and advanced welding technologies, understanding and mastering these essential techniques will distinguish professional welders from their peers, ensuring higher quality outcomes in their work.

Post-Welding Practices: Inspection and Maintenance for Quality Results

Post-welding practices play a crucial role in ensuring the quality and longevity of welded structures. According to a report by the American Welding Society, nearly 30% of welding defects are identified after the initial process, emphasizing the need for thorough inspection. Implementing a systematic approach to post-welding inspection can significantly reduce these defects. It’s essential to utilize techniques like visual inspection, non-destructive testing (NDT), and radiographic analysis to assess weld integrity. For instance, ultrasonic testing can detect internal flaws not visible to the naked eye, ensuring that welds meet the specified standards and enhancing overall durability.

Maintenance is equally important in the lifecycle of welded metal projects. A study presented at the International Conference on Welding Technology indicates that regular maintenance checks can extend the lifespan of welded structures by up to 50%. Maintaining proper environmental conditions, such as controlling humidity and temperature, can prevent corrosion and other environmental damage. Additionally, applying protective coatings post-welding not only improves aesthetics but also enhances resistance to wear and tear, thereby optimizing the performance of welded joints over time. By prioritizing thorough inspection and diligent maintenance, welders can guarantee quality results and greater safety in their projects.

Related Posts

-

Top 5 Best Welders for every Budget in 2023: Reviews and Buyer’s Guide

-

Understanding the Essential Components of MIG Welding Equipment for Beginners

-

Why Robotic Welding Machines Are Revolutionizing the Manufacturing Industry

-

7 Key Benefits of Robotic Welders: Transforming Manufacturing Efficiency in 2023

-

Spot Welding Machines: Revolutionizing Manufacturing Efficiency and Quality in 2023

-

2025's Ultimate Guide to the Top 10 Portable Spot Welders for Every DIYer

Contact us

Please fill out the enquiry form, and our dedicated team will promptly attend to your request