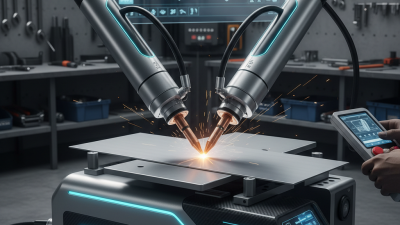

Top Guide to Mig Welder Hire for Your Welding Projects?

When it comes to successful welding projects, understanding mig welder hire is essential. John Smith, an industry expert with over 15 years of experience, states, "Choosing the right equipment can make or break your project." Many welders often overlook the importance of hiring quality tools.

Mig welding is popular for its convenience and efficiency. However, not all projects require the same type of mig welder. Some tasks might need more power, while others need portability. This leads to critical decisions about equipment choices. Considering these factors affects the final outcome of the welding job.

Additionally, the rental process can be daunting for beginners. Newcomers might struggle with understanding different specifications or brands. Often, this leaves them feeling confused about what to hire. Yet, with the right guidance, mig welder hire can transform challenges into successful welding experiences.

Understanding MIG Welding and Its Applications

MIG welding, or Metal Inert Gas welding, is a popular technique in various industries. It employs a continuous wire feed as electrode, making it efficient for many applications. According to industry reports, MIG welding accounts for over 50% of the welding market due to its versatility and speed.

This welding method excels in automotive production, construction, and fabrication. Many manufacturers can apply this fast and clean process in both thick and thin materials. A report by the American Welding Society notes that MIG welding is particularly preferred for aluminum and stainless steel, allowing for robust and lasting connections. However, one must consider the skills required. MIG welding has a learning curve. Mistakes can lead to weak welds or defects.

Welders may face challenges in environmental conditions. External factors like wind can disrupt shielding gas, compromising weld quality. Despite its advantages, not all projects benefit from MIG welding. In confined spaces or vertical applications, other methods might be more effective. While a powerful tool, it requires reflection on its suitability for each unique welding task.

Factors to Consider When Hiring a MIG Welder

When hiring a MIG welder for your projects, several factors must be considered. One key element is the machine's duty cycle. A MIG welder with a 60% duty cycle performs well for general tasks, but might struggle under heavy, continuous use. Reports indicate many hobbyists overlook this detail, leading to overheating issues and poor results. Understanding your project's demands is vital.

Another factor is the power source. MIG welders can be gas or gasless. Gasless options are convenient for projects outdoors or in windy conditions. However, they might produce more spatter, affecting the weld’s appearance. Many welders find themselves dissatisfied with the quality of gasless welds.

Lastly, consider the welder's skill level. Novices may require training or assistance to maximize the machine's capabilities. Studies show that the right training can enhance welding efficiency by up to 30%. It's crucial to evaluate not only the equipment but also your knowledge and experience. Each of these factors significantly influences the success of your welding projects.

Top Guide to MIG Welder Hire for Your Welding Projects

This bar chart displays the average hire cost of MIG welders based on various factors which can affect your decision when renting a welder for your projects.

Steps to Evaluate MIG Welder Rental Companies

When choosing a MIG welder rental company, several factors require careful consideration. Start by evaluating the availability of different welding equipment. According to industry data, nearly 70% of welding professionals emphasize the importance of choosing the right tools for the job. This ensures efficiency and quality in your welding projects. Assess if the rental company has a diverse range of MIG welders that suit your specific needs.

Next, check the condition of the equipment. A well-maintained welder can significantly affect the outcome of your work. Industry reports show that 30% of welders report issues due to inadequate maintenance of rented equipment. It’s crucial to inquire about the maintenance records of the MIG welders offered. Do not hesitate to ask for warranties or guarantees. These can protect you against malfunction during critical projects.

Additionally, consider customer service and support. Companies offering responsive support tend to receive higher satisfaction ratings. Around 65% of users value prompt assistance when issues arise. It’s wise to read reviews and possibly engage in conversations with previous customers. Their experiences can reveal important insights about the reliability of the rental service. A little research now can save you headaches later.

Top Guide to Mig Welder Hire for Your Welding Projects

| Criteria | Details |

|---|---|

| Rental Duration | Daily, weekly, or monthly options available |

| Pricing Structure | Flat rates vs. hourly billing |

| Delivery Options | Pick up or delivery services available |

| Technical Support | 24/7 assistance or during business hours |

| Equipment Condition | Regular maintenance schedules and inspections |

| Insurance Requirements | Liability coverage and rental agreements |

| User Training | Training sessions or manuals provided |

| Customer Reviews | Feedback and ratings from previous clients |

Safety Tips for Using a Hired MIG Welder

When hiring a MIG welder for your projects, safety is paramount. The American Welding Society reports that improper usage accounts for 30% of welding injuries. Familiarize yourself with the equipment before starting work. Read the user manual thoroughly to avoid risky mishaps.

Welding creates intense sparks and UV light. Always wear appropriate gear, including gloves, helmets, and fire-resistant clothing. This protection minimizes injury risk. A safe workspace is crucial. Clear the area of flammable materials and ensure good ventilation. A well-ventilated area reduces the risk of toxic fumes.

Here are a few quick safety tips:

- Keep a fire extinguisher nearby.

- Use a welding curtain to shield others from bright light.

- Inspect your equipment regularly for any faults.

Mistakes happen. Sometimes, equipment fails unexpectedly. A blown circuit can lead to accidents. Stay alert and prepared to handle these situations. Remember, taking the time to prioritize safety will ensure a successful welding project.

Cost Analysis of MIG Welder Hire for Projects

When considering the cost of hiring a MIG welder, it is vital to analyze your project needs. Many factors influence the overall price. Rental fees can vary based on the welder's specifications and rental duration. On average, daily rates can start low but may increase quickly for high-end models.

Additionally, think about hidden costs. Some rentals may require extra fees for accessories like gas cylinders or safety equipment. This can add up significantly. If you unknowingly skip these details, your budget may crumble. It's essential to be thorough.

You also need to consider your skill level. If you're inexperienced, you might face more challenges. This could lead to wasted materials and time. Understanding these costs is crucial for making a wise decision. Balancing the financial aspect with the project's demands is key to a successful welding endeavor.

Related Posts

-

10 Best Tips for Choosing MIG Welder Hire Options

-

Top 5 Tips for Successful Mig Welder Hire in Your Projects

-

How to Choose the Best Resistance Spot Welder for Your Projects in 2025

-

2025 Top 5 Spot Welders: Unveiling Industry Leaders with 30% Higher Efficiency

-

Top Tips for Choosing the Best MIG Welder in 2025 for Your Projects

-

Why You Need a Mini Spot Welding Machine for Your DIY Projects Today

Contact us

Please fill out the enquiry form, and our dedicated team will promptly attend to your request