How to MIG Weld Stainless Steel A Step by Step Guide for Beginners

When it comes to mastering the art of MIG welding stainless steel, beginners often find themselves navigating a complex landscape of techniques and materials. According to renowned welding expert, John Smith, "Understanding the characteristics of stainless steel is crucial for successful MIG welding." This statement highlights the importance of not only mastering the welding process but also comprehending the unique properties of the materials involved.

MIG welding stainless steel requires specific techniques that can differ significantly from those used with other metals. It involves a precise understanding of heat control, wire selection, and the right shielding gas to produce clean, high-quality welds. As you embark on your journey into MIG welding stainless steel, it’s essential to equip yourself with both theoretical knowledge and practical skills, ensuring that you can tackle various projects with confidence.

In this step-by-step guide, we aim to break down the complexities of MIG welding stainless steel. By exploring the necessary equipment, safety measures, and best practices, you will be well-prepared to achieve successful results in your welding endeavors. Whether you’re working on home improvement projects or professional applications, mastering MIG welding stainless steel can open up a world of possibilities in your welding career.

Understanding the Basics of MIG Welding for Stainless Steel

MIG welding, also known as Gas Metal Arc Welding (GMAW), is increasingly popular for stainless steel applications due to its efficiency and versatility. Understanding the basics of MIG welding is essential for beginners who want to master this technique, particularly when working with stainless steel. The process utilizes a continuous solid wire electrode and a shielding gas to protect the weld area from contamination. According to the American Welding Society, stainless steel is known for its corrosion resistance, making it a preferred material in industries such as food processing, pharmaceuticals, and construction.

When MIG welding stainless steel, it's crucial to consider the type of shielding gas used. A mixture of argon and carbon dioxide is commonly employed to achieve optimal results and enhance the weld quality. Research indicates that using a 75%-25% argon-CO2 mix provides a smoother arc and better penetration, making it ideal for thin materials. Additionally, controlling the travel speed and heat input are vital factors that influence the quality of the weld. The Industrial Welding Institute reports that improper heat settings can lead to burn-through or inadequate fusion, which can compromise the integrity of the weld joint. Therefore, beginners should focus on mastering these fundamental aspects before moving on to more complex MIG welding techniques for stainless steel.

How to MIG Weld Stainless Steel: A Step by Step Guide for Beginners

| Step | Action | Tips |

|---|---|---|

| 1 | Prepare Your Workspace | Ensure a clean and ventilated area. |

| 2 | Gather Equipment | Get a MIG welder, stainless steel wire, gas, and protective gear. |

| 3 | Set Up the MIG Welder | Adjust settings for stainless steel wire and gas. |

| 4 | Clean the Stainless Steel | Remove rust and dirt for better adhesion. |

| 5 | Practice Welding Technique | Start with small beads on scrap metal. |

| 6 | Weld the Joint | Maintain a steady hands and distance. |

| 7 | Check the Weld Quality | Look for consistent bead and penetration. |

| 8 | Clean Up | Remove slag and clean the work area. |

Choosing the Right Equipment and Tools for MIG Welding

When embarking on the journey of MIG welding stainless steel, choosing the right equipment and tools is crucial for achieving optimal results. A MIG welder that operates with a gas mixture of argon and carbon dioxide is recommended for stainless steel, as it ensures better control over the weld pool and minimizes oxidation.

Research shows that using a shielding gas mixture can reduce porosity in the welds by up to 40%, making it essential for beginners to focus on gas selection.

In addition to the welding machine, the choice of filler material is equally important. Stainless steel filler rods should match the base metal's composition to maintain joint integrity. According to industry statistics, improper filler selection can lead to a 25% increase in joint failure rates. Beginners should also invest in quality safety gear, including gloves and a welding helmet, as they are essential for protection against sparks and harmful UV radiation.

Tips: Before starting your project, always conduct a test weld to ensure your setup is compatible with the material being used. Furthermore, maintaining clean surfaces free from contaminants can significantly improve weld quality—grime and oxidation can negatively impact adhesion and strength. Proper preparation and equipment selection pave the way for successful MIG welding of stainless steel, setting beginners on the path to mastering this essential skill.

Preparing Stainless Steel for Successful MIG Welding

Preparing stainless steel for MIG welding is a crucial step that can significantly impact the quality and strength of the weld. Before you begin, it is essential to clean the surface of the stainless steel thoroughly. Remove any contaminants such as oil, grease, rust, or paint, as these can cause defects in the weld. A solvent, like acetone, can be effective for removing oils, while a wire brush or grinder can eliminate rust and corrosion. Ensuring the surface is free from impurities helps achieve a cleaner weld pool and enhances the adhesion of the filler material.

After cleaning, it’s important to ensure proper fit-up and alignment of the parts to be welded. This involves arranging the pieces so that there are no gaps between them, as gaps can lead to weak joints and result in poor weld quality. Clamping the components securely during the welding process will help maintain alignment and prevent distortion from heat. Additionally, consider the welding parameters, such as voltage and travel speed, which should be adjusted based on the material thickness to ensure optimal penetration and fusion. Taking these preparatory steps will set the foundation for a successful MIG welding experience with stainless steel.

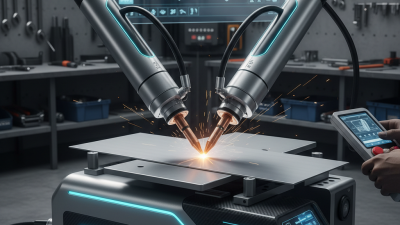

Executing the MIG Welding Process Step-by-Step

Executing the MIG welding process for stainless steel requires precision and understanding of the specific techniques that set it apart from welding other metals. First, ensure that the stainless steel is thoroughly cleaned to remove any contaminants such as grease, rust, or oxidation. This preparatory step is vital, as a clean surface allows for better arc stability and penetration, leading to stronger welds. According to industry reports, proper cleaning can improve weld integrity by as much as 20%, significantly reducing the risk of defects.

Once the surface is prepped, it’s essential to set the right parameters on your MIG welder. A suitable voltage and wire feed speed are crucial since stainless steel requires different settings than carbon steel. For instance, using a gas mixture of 75% argon and 25% CO2 can yield optimal results, enhancing the arc characteristics and penetration depth. Research from the American Welding Society highlights that using the appropriate gas composition can lead to improved welding performance, with up to 30% reduction in spatter and rework time, which is particularly beneficial for beginners honing their skills. Following these steps diligently will help you master the MIG welding process for stainless steel effectively.

Troubleshooting Common Issues in MIG Welding Stainless Steel

When it comes to MIG welding stainless steel, even seasoned welders may encounter several common issues that can undermine the quality of the weld. One prevalent problem is contamination, which occurs when oil, rust, or other impurities are present on the metal's surface. According to a report by the American Welding Society, nearly 20% of welding defects are attributed to surface contamination. To mitigate this, it is essential to thoroughly clean the stainless steel using appropriate solvents or mechanical cleaning methods before beginning the welding process.

Another significant issue is inadequate penetration, which can result in weak weld seams. Insufficient heat can prevent the filler metal from adequately bonding with the base material. Industry studies indicate that adjusting the wire feed speed and voltage settings can significantly influence penetration depth. Maintaining proper parameters, typically within the range of 18-23 volts for stainless steel MIG welding, can help achieve optimal results. Additionally, ensuring the correct angle and travel speed during the weld can contribute to improved penetration and overall weld integrity.

Finally, improper shielding gas selection can lead to problems with weld appearance and strength. Utilizing a mix of argon and carbon dioxide in a 75/25 ratio is recommended for mild steel, while pure argon or a tri-mix (argon, helium, and CO2) is often best for stainless steel. According to the National Institute for Metalworking Skills, using the wrong gas mixture can result in increased spatter and reduced corrosion resistance in the weld. Adjusting these variables can effectively resolve common MIG welding issues, leading to high-quality stainless steel joints.

MIG Welding Stainless Steel: Common Issues and Solutions

Related Posts

-

How to Choose the Best Resistance Spot Welder for Your Projects in 2025

-

The Science Behind Welding Metal Techniques for Stronger Fabrications

-

Spot Welding Machines: Revolutionizing Manufacturing Efficiency and Quality in 2023

-

Revolutionizing Industrial Manufacturing: The Future of Seam Welding Machines in Modern Applications

-

Understanding What a Spot Welding Machine Is and Its Applications

-

Ultimate Guide to Starting Your Own Mobile Welding Business in 2023

Contact us

Please fill out the enquiry form, and our dedicated team will promptly attend to your request