Why You Need a Mini Spot Welding Machine for Your DIY Projects Today

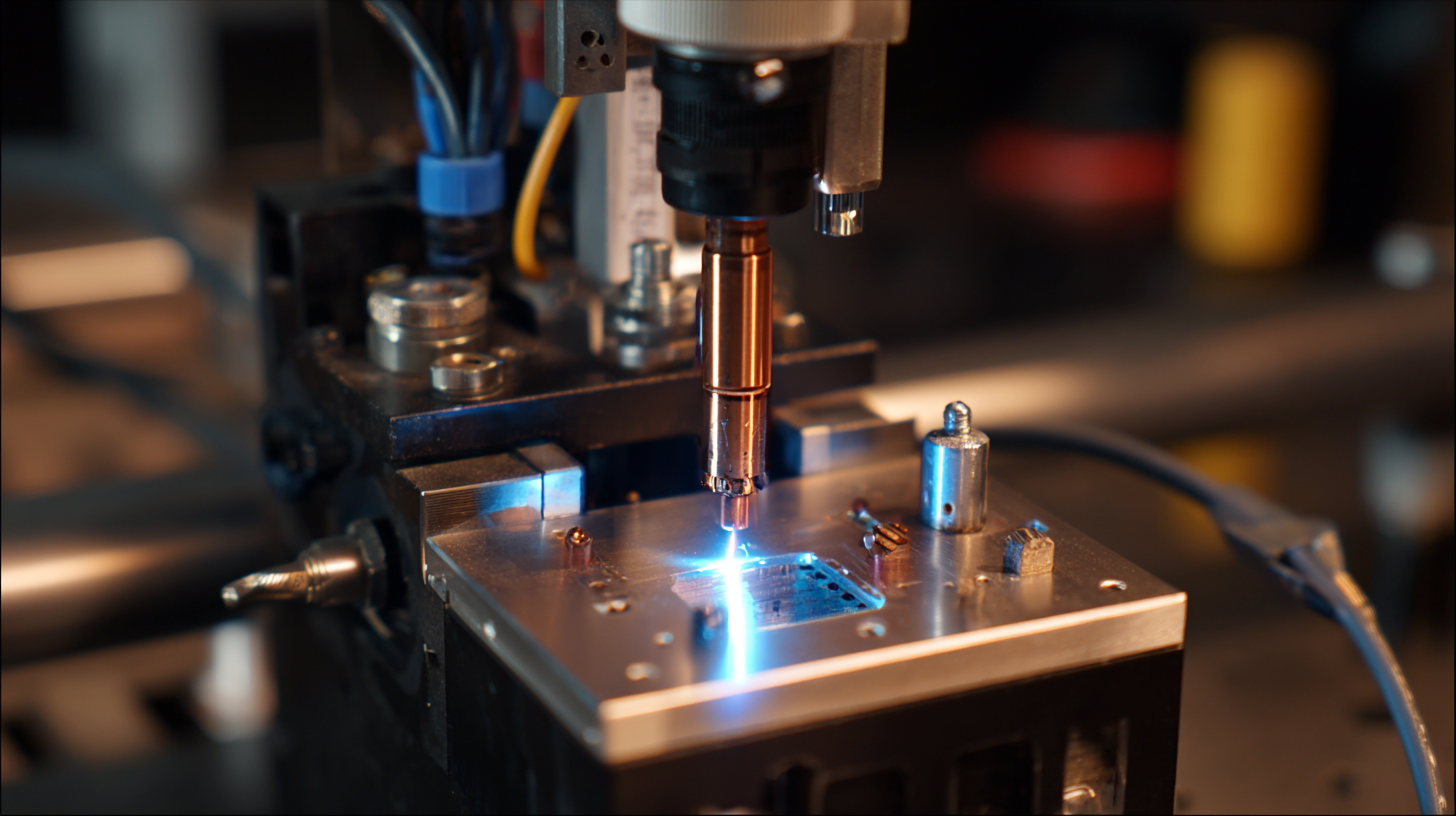

When it comes to tackling DIY projects, having the right tools is crucial for achieving professional results. One tool that stands out for both amateur and seasoned makers is the mini spot welding machine. This compact but powerful device offers great versatility and efficiency, making it indispensable for various applications, from crafting metal art to repairing automotive parts. In the ever-evolving landscape of DIY tools, knowing why you need a mini spot welding machine today can elevate your projects and streamline your workflow.

With the rise in popularity of custom fabrication and upcycling, the mini spot welding machine has gained traction among DIY enthusiasts. Its ability to create strong, reliable welds in tight spaces and on small components makes it ideal for intricate tasks that larger machines simply can’t handle. As we delve into the top ten reasons why you should consider incorporating a mini spot welding machine into your toolkit, you’ll discover how this tool can revolutionize your approach to DIY and enhance your overall craftsmanship. Whether you're a hobbyist looking to expand your capabilities or a professional in need of a reliable portable solution, the advantages of this versatile tool are undeniable.

Benefits of Using a Mini Spot Welding Machine for DIY Enthusiasts

A mini spot welding machine can be a game-changer for DIY enthusiasts, providing numerous benefits that elevate your projects to a professional level. According to a 2022 report from the American Welding Society, around 100,000 new welders enter the market each year, with an increasing number gravitating towards miniaturized welding solutions for home use. These machines are designed for precision and convenience, allowing users to create strong, durable welds without the need for extensive training or experience.

One significant advantage of using a mini spot welding machine is its compact size, which makes it easy to store and handle. This portability allows DIY enthusiasts to work in tighter spaces, making it ideal for various projects, from jewelry making to automotive repairs. Additionally, many modern mini spot welders are equipped with advanced safety features, reducing the risk of accidents in a home workshop environment.

**Tip:** Always read the user manual and follow safety protocols when using a mini spot welding machine. Start with scrap metal to practice your technique before moving on to crucial parts of your project. This will help you develop a steady hand and a better understanding of the machine's capabilities.

Using a mini spot welding machine also significantly reduces the time spent on a project. Research indicates that traditional welding methods can take up to three times longer than spot welding for specific applications. By investing in a mini spot welder, DIY enthusiasts can increase productivity while maintaining high-quality results.

Why You Need a Mini Spot Welding Machine for Your DIY Projects Today

| Benefit | Description | Ideal For |

|---|---|---|

| Portability | Easy to carry and use in various locations. | DIY enthusiasts who work on site. |

| Precision | Allows for accurate welding on small parts. | Fine detail projects. |

| Cost-Effective | Affordable for small budgets while still delivering quality results. | Hobbyists and beginners. |

| Versatility | Works on various materials such as metal, copper, and more. | Multi-material projects. |

| User-Friendly | Simple controls make it easy for beginners to use. | Beginners and casual users. |

Key Features to Look for in a Mini Spot Welding Machine

When searching for a mini spot welding machine for your DIY projects, it's essential to focus on several key features that can enhance your experience and outcomes.

First and foremost, consider the power output of the machine. A higher wattage ensures that the device can effectively weld thicker materials. Look for machines that offer adjustable power settings, allowing you to fine-tune the welding process for different materials, from thin sheets to heavier components.

Another critical feature is the welding tip quality and design. A good mini spot welding machine should come with durable, interchangeable tips that suit various welding tasks. This versatility not only extends the machine's lifespan but also increases its functionality. Additional features like a lightweight, portable design are also a plus, enabling ease of use and storage.

An integrated cooling system may further enhance performance by preventing overheating during prolonged welding sessions, making the machine a reliable companion for all your creative endeavors.

Top Applications of Mini Spot Welding Machines in Home Projects

Mini spot welding machines have become invaluable tools for DIY enthusiasts, providing precision and efficiency in various home projects. One of the primary applications is metal fabrication, where these machines are used to join thin sheets of metal seamlessly. Whether creating custom furniture, repairing appliances, or crafting artistic metal sculptures, the ability to weld without the need for extensive equipment makes these machines essential.

Another significant application lies in automotive repairs. Mini spot welders are perfect for fixing small parts, such as brackets and panels, which require strong, yet localized welding. Their compact size allows for easy maneuverability in tight spaces, making them an ideal choice for hobbyists working on car restorations or modifications. Additionally, they are useful in creating electrical connections, as they can weld battery terminals and connectors effectively, ensuring robust and reliable results in a DIY setting.

How to Choose the Right Mini Spot Welder for Your Needs

When it comes to choosing the right mini spot welder for your DIY projects, understanding your specific needs is crucial. There are various factors to consider, such as the thickness of the materials you will be welding, the power output of the welder, and its versatility. A good mini spot welder should accommodate a range of materials for diverse applications, making it an essential tool for any DIY enthusiast.

Additionally, as the manufacturing industry shifts towards smart and precise solutions, reliable tools become indispensable. Mini spot welders are particularly beneficial for projects involving intricate designs or sensitive materials, providing clean and efficient welds. By selecting a model that equally balances performance and ease of use, you can enhance your DIY experience and achieve professional-level results in your home projects. Investing time in researching and understanding the options available will ensure you make an informed choice tailored to your specific welding needs.

DIY Projects with Mini Spot Welding Machines

Tips for Safe and Effective Use of Mini Spot Welding Machines

When it comes to DIY projects, a mini spot welding machine can be an invaluable asset. However, to ensure a safe and effective operation, it’s crucial to follow some important guidelines. According to a report by the American Welding Society (AWS), improper use of welding equipment is a leading cause of workplace injuries, accounting for approximately 38% of all welding-related incidents. Therefore, understanding how to operate a mini spot welder safely should be a priority for every DIY enthusiast.

First and foremost, always wear appropriate personal protective equipment (PPE). This includes gloves, safety glasses, and, if necessary, a welding helmet to guard against sparks and intense light. Additionally, it's essential to work in a well-ventilated area to avoid the buildup of harmful fumes and gases. The National Institute for Occupational Safety and Health (NIOSH) emphasizes the importance of ventilation, noting that effective airflow can reduce exposure to harmful particles by up to 60%.

Furthermore, familiarize yourself with the specific settings on your mini spot welding machine. Adjusting parameters like voltage and pressure according to the materials you're working with can significantly impact the quality of your welds. A study from the Welding Research Council shows that optimal machine settings can increase weld strength by around 25%, making it essential to understand how to tailor your equipment to your project's needs. Following these tips will not only enhance your welding experience but also help keep you safe throughout your DIY endeavors.

Related Posts

-

Spot Welding Machines: Revolutionizing Manufacturing Efficiency and Quality in 2023

-

Ultimate Guide to Starting Your Own Mobile Welding Business in 2023

-

Understanding the Essential Components of MIG Welding Equipment for Beginners

-

7 Key Benefits of Robotic Welders: Transforming Manufacturing Efficiency in 2023

-

Unlocking the Future: How Automotive Welding Technologies Are Revolutionizing Vehicle Manufacturing

-

The Science Behind Welding Metal Techniques for Stronger Fabrications

Contact us

Please fill out the enquiry form, and our dedicated team will promptly attend to your request