Top 10 Resistance Spot Welder Tips for Beginners

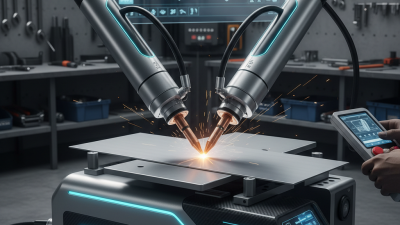

When beginning your journey with a resistance spot welder, it’s essential to grasp the basics. The right approach can drastically improve your welding skills. Understanding the mechanics of resistance spot welding is crucial. It involves a combination of heat and pressure to create strong joints between metals.

Many newcomers face challenges, often leading to frustration. Common mistakes include using incorrect settings or not preparing materials properly. It’s important to take time for practice. Experimenting with different techniques can enhance your confidence and results. Keep in mind that every weld may not be perfect, and that’s okay. Each attempt is a chance to learn.

Safety should also be a priority while working with a resistance spot welder. Protective gear is necessary to prevent injuries. Remember, every expert was once a beginner. Embrace the journey, remain patient, and allow yourself to grow through experience. Taking notes on your progress can help identify areas for improvement.

Understanding the Basics of Resistance Spot Welding for Beginners

Resistance spot welding is a key process in metal fabrication. This technique joins two or more metal sheets by applying heat generated from resistance to electric current. Beginners should grasp its fundamentals to improve their skills quickly. According to industry reports, resistance spot welding has an efficiency rate of about 90%. This makes it an attractive choice for manufacturers.

Tip: Ensure proper alignment of the metal sheets before welding. Misalignment can lead to weak joints. Always check the machine settings before starting. The right pressure and current are crucial. Even slight changes can impact the outcome.

Safety is vital in this process. Beginners often underestimate the risks involved. Personal protective equipment, like gloves and goggles, is essential. Moreover, it's important to regularly inspect equipment for wear and tear. Neglecting maintenance can lead to serious accidents.

Tip: Practice on scrap pieces of metal. This helps you understand the heat settings and timing better. Remember, every mistake can teach you something valuable. Embrace the learning curve to become proficient in resistance spot welding.

Top 10 Resistance Spot Welder Tips for Beginners

| Tip Number | Tip Description | Expected Outcome |

|---|---|---|

| 1 | Familiarize yourself with the equipment | Improved safety and efficiency |

| 2 | Adjust the settings according to the material | Better weld strength |

| 3 | Clean the surfaces to be welded | Increased conductivity and bond quality |

| 4 | Use proper electrode tips | More precise welding |

| 5 | Practice the right welding techniques | Improved skills and confidence |

| 6 | Monitor the pressure applied during welding | Consistent weld quality |

| 7 | Select appropriate welding time | Cycle time optimization |

| 8 | Keep the welding area clear | Enhanced safety |

| 9 | Inspect the welds regularly | Early detection of issues |

| 10 | Understand the limits of the machine | Informed decision making |

Essential Safety Precautions When Using Resistance Spot Welders

When working with resistance spot welders, safety should be a priority. Wear proper protective gear. This includes gloves, goggles, and a face shield. Sparks and heat can create hazards quickly. Loose clothing should be avoided. Fumes and gases can also pose risks, so ensure good ventilation.

Inspect your equipment before use. Check for loose connections or damaged cables. A faulty welder can lead to accidents. Remember, the workspace matters. Keep flammable materials away. Establish a clean area to work in. Distractions can increase mistakes.

Be cautious around high amounts of electricity. Understand the consequences of improper handling. If you feel unsure, seek guidance. Practice makes perfect, but safety must come first. Keep your focus, and always have a plan. With the right precautions, spot welding can be a successful venture for beginners.

Choosing the Right Equipment: A Beginner's Guide to Spot Welders

Choosing the right equipment for spot welding is crucial for beginners. There are various types of spot welders available on the market. Each type has unique specifications that suit different projects. According to a recent industry report, nearly 40% of new welders select equipment that does not meet their project requirements. This often results in subpar welds and wasted materials.

When selecting a spot welder, it’s important to consider output power. Different tasks demand specific power levels. Studies show that welders with adjustable power settings can improve the quality of welds by up to 50%. Ensure you understand the thickness of the materials you'll be working with. Beginners often underestimate this factor, leading to weak joints and increased rework.

Portability is another factor. Some welders are heavy and cumbersome. While they may offer high performance, they can be impractical for DIY projects. A lightweight option is easier to maneuver. Look for units that balance power and ease of use. Remember, the most expensive equipment isn't always the best choice. Reflect on what you truly need for your projects. A focused approach will enhance your welding journey.

Top 10 Resistance Spot Welder Tips for Beginners

Techniques for Achieving Strong Welds and Avoiding Common Mistakes

Achieving strong welds is crucial for any beginner using a resistance spot welder. Understanding the machine's settings is key. Adjust the pressure and current according to the material thickness. Too much pressure can warp the metal. Too little will result in weak welds. Grip the material firmly to avoid movement during the process.

Practicing on scrap materials is essential. You can learn by making mistakes without the pressure of a final product. Experiment with different settings. Some welds might look good but fail when tested. Pay attention to the molten puddle that forms during welding. A consistent, smooth puddle indicates correct settings. If it's uneven or splattered, recheck your adjustments.

Common mistakes often arise from impatience. Rushing the process can lead to overheating or poor quality welds. Take your time and focus on each joint. Cleaning the metal before welding is vital. Contaminants can weaken the weld. Use a wire brush or grinder to prepare the surface. This small step can significantly improve your results.

Maintaining Your Resistance Spot Welder for Longevity and Efficiency

Maintaining your resistance spot welder is crucial for ensuring its longevity and efficiency. Regular maintenance helps you avoid unexpected breakdowns. Always clean the electrodes after each use. Residue can build up and affect performance. Inspect cables and connections for wear. Damaged wires can lead to dangerous situations.

Check the water cooling system. Ensure it functions properly to prevent overheating. If the welder gets too hot, it can shorten its lifespan. Keep track of the welder's usage. Overworking the machine can lead to fatigue and malfunctions. Listen for unusual sounds. A noise may indicate that something isn't right.

Store the welder in a dry place. Moisture can cause rust and damage components. Use protective covers when not in use. This can help dust and contaminants from settling. If you notice any irregularities, don’t ignore them. Promptly addressing issues can save time and money. Take a moment to reflect on your practices. Are you doing enough to care for your equipment?

Related Posts

-

2025 How to Choose the Right Resistance Spot Welder for Your Needs

-

2025 Best Spot Welder Guide for Homeowners and DIY Enthusiasts

-

Why You Need a Mini Spot Welding Machine for Your DIY Projects Today

-

2025 Guide: How to Choose the Best Automotive Spot Welder for Your Needs

-

2025 Top 5 Spot Welders: Unveiling Industry Leaders with 30% Higher Efficiency

-

How to Choose the Best Resistance Spot Welder for Your Projects in 2025

Contact us

Please fill out the enquiry form, and our dedicated team will promptly attend to your request