Understanding What a Spot Welding Machine Is and Its Applications

In the evolving landscape of manufacturing, the importance of efficient and reliable joining techniques cannot be overstated. The spot welding machine stands at the forefront of this domain, providing a robust solution for various industrial applications, particularly in the automotive and electronics sectors. According to a report by MarketsandMarkets, the global spot welding equipment market is projected to reach USD 2.5 billion by 2025, growing at a significant rate. This growth can be attributed to the increasing demand for high-quality, durable welds that ensure the structural integrity of components while minimizing production costs.

Spot welding machines utilize a process that involves the application of heat and pressure to join metal surfaces, making them indispensable in industries where strength and precision are paramount. The versatility of these machines enables them to cater to a wide range of materials, from thin sheets of stainless steel to aluminum alloys, which are commonly used in vehicle manufacturing. The ability to quickly and efficiently produce high-strength welds has established spot welding as a preferred method for assembly lines, showcasing its critical role in enhancing productivity and maintaining quality standards in modern fabrication processes. As technology advances, the integration of smart manufacturing practices is expected to further optimize the performance and capabilities of spot welding machines, reinforcing their significance in future industrial applications.

What is Spot Welding and How Does It Work?

Spot welding is a form of resistance welding that joins pieces of metal by applying pressure and a concentrated electric current at specific points. This process generates localized heat, causing the metal to melt and fuse together, forming a strong bond. Typically used in manufacturing, spot welding is particularly effective for assembling sheet metal components, making it a staple in the automotive industry. The efficiency of spot welding lies in its ability to quickly and reliably process components without extensive prep work.

Recent advancements in technology, such as the Intelligent Resistance Welding Inspection system, have further enhanced the spot welding process. This innovative system integrates robotic welding with real-time data collection and artificial intelligence, allowing manufacturers to monitor the welding process continuously. By ensuring quality control during welding, the system helps improve both the efficiency and quality of the final products. As a result, automakers can achieve higher precision and reduce the risk of defects, leading to more reliable and durable vehicle assemblies.

Spot Welding Applications and Efficiency Overview

Key Components of a Spot Welding Machine

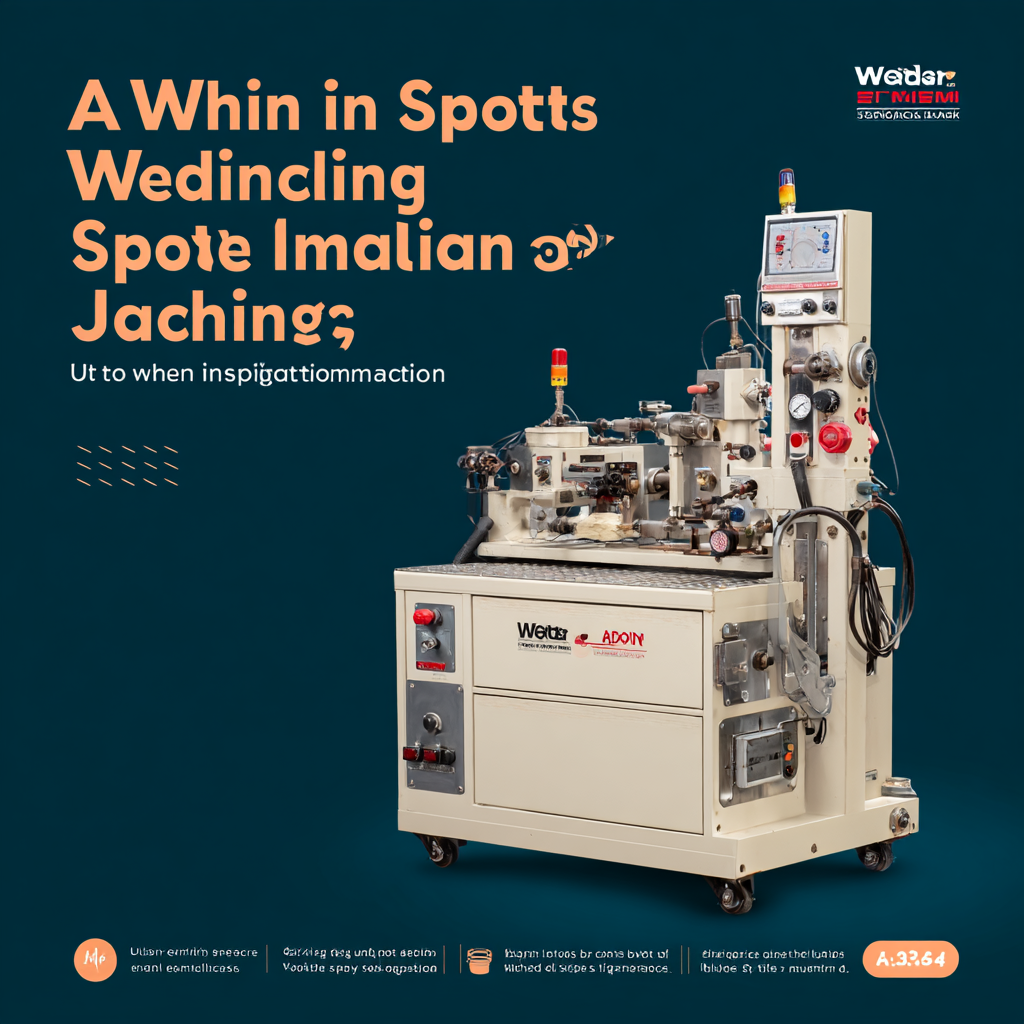

Spot welding machines are vital in the manufacturing sector, particularly in automotive and electronics industries where metal joining is essential. The key components of a spot welding machine include the electrode, transformer, control system, and cooling system. Each plays a critical role in ensuring effective welding operations.

Spot welding machines are vital in the manufacturing sector, particularly in automotive and electronics industries where metal joining is essential. The key components of a spot welding machine include the electrode, transformer, control system, and cooling system. Each plays a critical role in ensuring effective welding operations.

The electrodes are responsible for applying pressure and delivering the welding current to the workpieces. Typically made from copper, they can withstand high temperatures and electrical conductivity. According to a 2022 report from Smithers, the global demand for spot welding machines is projected to grow by 5.2% annually, highlighting the increasing reliability and efficiency of these components. The transformer, on the other hand, converts the high-voltage current to a low-voltage current suitable for welding, ensuring that the energy is effectively used to create a strong bond.

The control system is another significant component, allowing operators to adjust parameters such as current intensity and welding time. This system is crucial for achieving optimal weld quality while minimizing defects. Additionally, cooling systems prevent overheating of the electrodes, thereby prolonging their lifespan. With the rise of automation in manufacturing, these components are more sophisticated than ever, contributing to the growing trend of spot welding machinery that meets industry standards while enhancing productivity.

Varied Applications of Spot Welding in Industries

Spot welding has become an essential technique in various industries due to its versatility and efficiency. The automotive sector is perhaps the most significant user, where engineers rely on spot welding for assembling components quickly and effectively. This method allows for strong, permanent joins between metal parts, which is crucial in manufacturing vehicles that require durability and safety. As industries look to enhance productivity, spot welding robots are gaining traction, significantly increasing precision and reducing labor costs.

Beyond automotive manufacturing, spot welding finds applications in electronics, construction, and furniture production. In electronics, for instance, it plays a vital role in joining thin metals and components without causing thermal damage, ensuring product reliability and longevity. The growing demand for lightweight materials in various sectors is also driving the need for innovative welding solutions, including resistance and laser spot welding technologies. As industries continue to evolve, the applications of spot welding are expected to expand further, reinforcing its importance in modern manufacturing practices.

Understanding What a Spot Welding Machine Is and Its Applications

| Industry | Application | Benefits | Common Materials |

|---|---|---|---|

| Automotive | Welding of sheet metal parts | High strength joints, fast production | Steel, Aluminum |

| Construction | Manufacturing prefabricated structures | Enhanced structural integrity | Steel |

| Electronics | Joining electronic components | Precision, minimal heat distortion | Copper, Aluminum |

| Aerospace | Assembly of airframe components | Lightweight construction | Aluminum alloys, Titanium |

| White Goods | Manufacturing appliances (e.g., refrigerators) | Cost-effective, high-volume production | Stainless steel, Mild steel |

Advantages of Using Spot Welding Machines

Spot welding machines offer numerous advantages that make them essential in various industries, particularly in metal fabrication. One of the primary benefits is their speed; these machines can quickly join two pieces of metal together through the application of heat generated by electrical resistance. This efficiency not only increases productivity but also reduces the overall production time, allowing manufacturers to meet tight deadlines.

Additionally, spot welding machines provide strong and reliable welds, which is crucial in applications such as automotive and aerospace manufacturing. The quality of the welds contributes to the structural integrity of the products being assembled. Furthermore, these machines are often automated, which minimizes human error and ensures consistency in weld quality. The ability to repeat the same process with precision is a significant advantage, making spot welding machines a preferred choice for high-volume production environments.

Top 5 Spot Welding Machines to Consider in 2025

When considering spot welding machines for 2025, it's essential to evaluate the latest technologies and features that enhance effectiveness and efficiency. The advancement in inverter technology and control systems makes modern machines more user-friendly and adaptable to various materials.

A top choice is the Miller Spot Welder, known for its durability and precision in automotive applications. Another contender is the Lincoln Electric Machine, which offers robust performance and easy setup, ideal for both experienced professionals and beginners.

A top choice is the Miller Spot Welder, known for its durability and precision in automotive applications. Another contender is the Lincoln Electric Machine, which offers robust performance and easy setup, ideal for both experienced professionals and beginners.

Tips for selecting the right spot welding machine include assessing the intended application and material thickness. Machines with adjustable power settings provide flexibility for different tasks. Additionally, consider models with built-in safety features to ensure the well-being of operators.

Other noteworthy options include the ESAB Spot Welder, celebrated for its compact design and portability, making it suitable for smaller workshops. The Hobart 500559 also stands out for its excellent performance in varied industrial applications. Evaluating these machines based on user reviews and technical specifications can greatly assist in making an informed decision.

Related Posts

-

Spot Welding Machines: Revolutionizing Manufacturing Efficiency and Quality in 2023

-

Revolutionizing Industrial Manufacturing: The Future of Seam Welding Machines in Modern Applications

-

Unlocking the Future: How Automotive Welding Technologies Are Revolutionizing Vehicle Manufacturing

-

Ultimate Guide to Mobile Welding Techniques for Every DIY Enthusiast

-

Why Robotic Welding Machines Are Revolutionizing the Manufacturing Industry

-

Unveiling the Best Spot Welder for Home Projects with Essential Insights and Expert Tips

Contact us

Please fill out the enquiry form, and our dedicated team will promptly attend to your request