Top 7 Tips for Mig Welding Stainless Steel Successfully?

MIG welding stainless steel can be a rewarding skill. However, many beginners face challenges that may derail their efforts. To achieve high-quality welds, understanding specific techniques is crucial.

Using the right equipment plays a vital role. An ideal welder should have controls for voltage and wire speed. Additionally, choosing the correct filler metal type can make a significant difference. It’s imperative to select a compatible grade of stainless steel.

Many welders overlook crucial details, such as surface preparation. Clean surfaces ensure better metal fusion. Neglecting proper cleaning could lead to weak welds. Knowledge and practice are key. Understanding the importance of heat control is also necessary. Too much heat causes warping, while too little causes poor penetration. Mastering MIG welding stainless steel requires patience and attention to these details.

Understanding the Basics of MIG Welding Stainless Steel

MIG welding stainless steel can be both rewarding and challenging. Understanding the basics is essential for successful outcomes. Stainless steel is known for its corrosion resistance and high durability, but it also presents unique challenges. According to industry reports, improper settings can lead to poor weld quality.

Tip: Choose the right filler material. Stainless steel requires a compatible filler to ensure strong bonds. Using incorrect filler can result in weak welds. Additionally, keep a consistent travel speed. Uneven movement can cause excessive heat or cold laps, leading to structural weaknesses.

Understanding the machine settings is crucial. Voltage, wire speed, and gas flow must align with the workpiece. A study showed that incorrect voltage settings can increase production costs by up to 20%. Adjustments based on material thickness can make a significant impact.

Tip: Practice good cleanliness. Oil, grease, or rust can contaminate the weld and reduce effectiveness. Clean surfaces enhance adhesion. A weld technique must also be mastered. Overlapping may look appealing but compromises integrity. Regular assessments of your work will foster improvement and skill development.

Choosing the Right Equipment and Materials for Successful Welding

When it comes to MIG welding stainless steel, choosing the right equipment is vital. A suitable welding machine is essential for a quality finish. Ensure it can handle stainless steel's specific properties. Also, pay attention to the type of shielding gas you use. The right gas mix will influence bead appearance and penetration. Argon or a mix of argon and carbon dioxide are common choices.

Selecting the right filler material is equally important. Stainless steel rods differ in composition. A mismatch in materials can lead to poor adhesion and corrosion issues. Look for filler that matches your base metal. A good match can produce cleaner welds.

It's worth noting that even with the best equipment, mistakes can happen. Improper settings can lead to weak joints. Be ready to reassess and adjust your technique. Practice makes perfect, but each project can bring unique challenges. Reflecting on your work can help you improve.

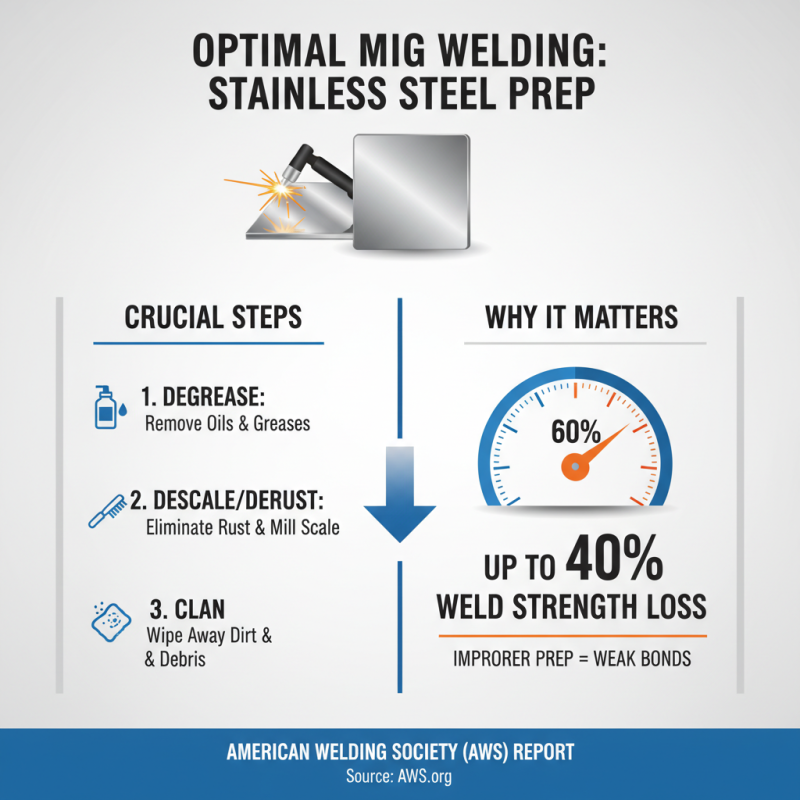

Preparing the Stainless Steel Surface for Optimal Weld Quality

Preparing the stainless steel surface properly is crucial for achieving optimal weld quality in MIG welding. The American Welding Society reports that improper surface preparation can reduce weld strength by up to 40%. This underlines the importance of removing contaminants. Oils, rust, and dirt can all compromise the bond during welding.

Start by cleaning the surface thoroughly. Use solvents or degreasers to eliminate any grease or oil. An abrasive scrub with stainless steel brushes can remove rust. However, if not done properly, this can lead to scratches. These imperfections may affect the finish and integrity of the weld. Ensure the area is dry before welding. Moisture can create porosity in the weld.

Next, consider the use of a proper grinding technique. Grinding not only cleans but also prepares the surface for better penetration. However, be cautious. Too much grinding can lead to heat buildup. This can affect the steel's properties. The ideal surface roughness should range from 0.1 to 0.5 micrometers, according to industry standards. Achieving this may require practice and adjustment.

Adjusting Settings for Optimal MIG Welding Performance

When MIG welding stainless steel, your settings play a crucial role in achieving quality results. Start by adjusting the voltage and wire feed speed. Each metal thickness may require unique settings. A good rule is to start with lower voltage and gradually increase it. Too much voltage can lead to burn-through. Keep an eye on the arc's stability as you make adjustments.

Gas selection also matters. A mixture of argon and CO2 can enhance the weld's appearance. The correct gas flow rate ensures a clean weld without contamination. Inspect your shielding gas delivery system; leaks affect performance. Remember, finding the perfect balance takes time and practice.

Also, consider your welding speed. Going too fast may lead to weak spots, while going too slow can cause excessive heat. Maintain a steady hand and keep a consistent distance from the workpiece. A shaky hand can ruin an otherwise good weld. It’s okay to make mistakes; they are part of learning. Reflect on each weld and adjust your technique accordingly.

Common Challenges and Solutions in MIG Welding Stainless Steel

MIG welding stainless steel presents unique challenges. One common issue is distortion.

Because stainless steel reacts differently to heat, it can warp easily. Utilizing proper heat settings can minimize this. A good tip is to start with

lower amperage and slowly increase it to avoid excessive heat.

Another challenge is the appearance of burn-through. Thin stainless steel is prone to this problem. To combat this,

use a backing bar. It helps absorb heat and reduces the risk of burn-through. Also, consider moving quickly along

the weld seam to control heat input better.

Welding with the wrong filler metal can lead to poor results. Ensure you select a filler that

matches your base material. Pay attention to the stainless steel grade you're working with. Not all fillers are compatible.

Lastly, remember that practice leads to improvement. Review your technique frequently. Adjusting your approach as you learn will lead to better results.

Related Posts

-

Top 10 Resistance Spot Welder Tips for Beginners

-

Revolutionizing Industrial Manufacturing: The Future of Seam Welding Machines in Modern Applications

-

Spot Welding Machines: Revolutionizing Manufacturing Efficiency and Quality in 2023

-

Why Choose a Resistance Spot Welder for Your Welding Projects

-

Understanding What a Spot Welding Machine Is and Its Applications

-

The Science Behind Welding Metal Techniques for Stronger Fabrications

Contact us

Please fill out the enquiry form, and our dedicated team will promptly attend to your request