2026 Top Mig Welding Stainless Steel Techniques and Tips?

MIG welding stainless steel is a crucial skill for any metalworking enthusiast. In 2026, advancements in technology and techniques continue to shape this trade. However, even with these advancements, mastering MIG welding stainless steel remains a challenge for many.

The process requires precision and an understanding of the material. Stainless steel is different from mild steel; it needs special attention. Using the right shielding gas and settings is vital for a strong weld. Overheating can lead to warping or burn-through, which can ruin an entire project. It's essential to reflect on common mistakes and learn from them.

Practical experience is invaluable. Try various techniques and see what works best. Revise your approach based on results. This process of trial and error is key to becoming proficient in MIG welding stainless steel. Remember, every welder faces challenges. Embracing these challenges can lead to significant improvement.

Understanding the Basics of MIG Welding for Stainless Steel

MIG welding stainless steel is an essential skill for many fabricators. Understanding the basics is critical. The process often uses a solid wire electrode. This kind of welding produces high-quality welds with minimal spatter. According to industry reports, MIG welding accounts for about 70% of stainless steel welding applications today.

When starting, ensure your machine settings match the material thickness. Improper settings can lead to weak welds. For instance, a wire feed speed that's too high may create burn-through. Keep your travel speed steady. This is crucial for achieving a consistent bead appearance.

Tips: Always clean the stainless steel surface. Remove any contaminants to prevent defects. Use a backhand welding technique for better penetration. Remember to check for shielding gas leaks, as they can affect weld quality. Prioritizing these aspects leads to effective and strong welds, ensuring long-lasting results. Yet, even experienced welders must continually refine their techniques. Each project offers learning opportunities and room for improvement.

2026 Top Mig Welding Stainless Steel Techniques and Tips

| Technique | Description | Tips | Common Applications |

|---|---|---|---|

| Short Circuit Transfer | Ideal for thin materials, offering good control and minimal distortion. | Maintain a steady arc length; use a fast travel speed. | Stainless steel sheets in automotive applications. |

| Metal Spray | Uses a spray of molten metal to create strong welds. | Practice bead control; adjust gas flow to prevent porosity. | Manufacturing industries, especially in pipeline applications. |

| Pulsed MIG Welding | Reduces heat input and prevents warping, suitable for thin materials. | Set the pulse perfectly; control wire feed speed accurately. | Used in high-end automotive parts and aerospace components. |

| Weaving Technique | Creates a zig-zag pattern for filling wider joints effectively. | Control speed and width of weave for consistent bead appearance. | Ideal for thicker plates in construction and structural work. |

| Backing Bars | Support for the weld during cooling; helps to prevent warping. | Use the correct material; align precisely with the joint. | Common in heavy fabrication like tanks and vessels. |

Essential Equipment and Materials for Quality MIG Welding

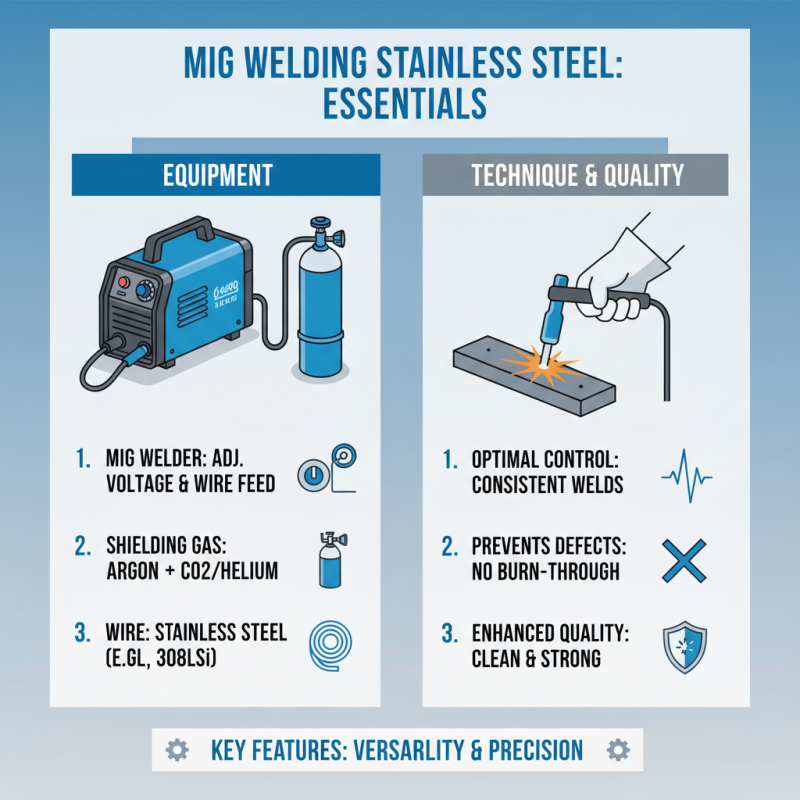

MIG welding stainless steel requires specific equipment and materials. Choosing the right tools can greatly enhance welding quality. A good MIG welder should provide optimal control and versatility. Look for features like adjustable voltage and a smooth wire feed. This will prevent issues like inconsistent welds or burn-through.

In addition to the welder, suitable shielding gas is crucial. A mix of argon and CO2 is often recommended. Reports indicate that this mixture improves arc stability. It also reduces spatter. Using appropriate filler wire is equally important. ER308L is a popular choice for stainless steel. It offers excellent corrosion resistance and is easier to work with.

Beyond tools, workspace matters too. Ensure proper ventilation to avoid toxic fumes. A clean surface helps achieve better weld penetration and strength. Feedback from experienced welders suggests that maintaining a clutter-free environment can positively impact the quality of the weld. If you encounter issues, don’t hesitate to reassess your setup. The right adjustments can lead to significant improvements in your results.

Step-by-Step Guide to Preparing Stainless Steel for Welding

Preparing stainless steel for MIG welding requires attention to detail. Cleanliness is crucial. Use a degreaser to remove oil, grease, and dirt. Even small contaminants can lead to imperfections. A clean surface improves weld quality significantly.

Next, you need to grind the edges. Use a flap disc or grinding wheel. This creates a better surface for the weld. Pay attention to the bevel angle. Too steep or too shallow can cause problems. Take your time to get it right.

Finally, consider proper fit-up. Gaps and misalignment create issues during welding. Use clamps to hold pieces in place. Check alignment multiple times. This process is crucial for a successful weld and often overlooked. Reflecting on these steps can help avoid frustrating mistakes later.

2026 Top Mig Welding Stainless Steel Techniques

This chart illustrates the importance ratings of various techniques in MIG welding stainless steel as of 2026. Each technique is rated on a scale from 1 to 10, indicating the significance of preparation and safety measures in achieving high-quality welds.

Techniques for Achieving Quality Welds in Stainless Steel

Achieving quality welds in stainless steel requires practice and attention to detail. When starting, ensure the surface is clean. Use a suitable cleaner to remove contaminants. Even small amounts of grease can ruin a weld. A clean surface is essential for strong adhesion and a clean finish.

Another aspect to consider is the settings on your MIG welder. It's crucial to find the right wire speed and voltage. Too high settings can lead to burn-through. Too low can create weak welds. Experimenting with settings will lead to better results. Understanding your equipment helps in making quick adjustments during welding.

Another common mistake is poor feeding technique. Watch for kinks or tangles in the wire. Regularly check the feeding mechanism for smooth operation. Inconsistent wire feed can cause weld splatter or weak spots. Each weld presents a learning opportunity. Reflection on what worked and what didn't is vital for improvement. Embrace imperfections as steps toward mastering stainless steel welding.

Common Mistakes to Avoid When MIG Welding Stainless Steel

MIG welding stainless steel can be tricky. Many welders make common mistakes that can lead to poor results. One common error is not cleaning the metal properly before welding. Contaminants like oil, grease, or rust will cause defects. Take time to clean the surface. Use a stainless steel brush for best results.

Another mistake is using incorrect settings on the welding machine. Adjusting voltage and wire speed is crucial. If the settings are off, it can lead to burn-through or weak welds. Pay attention to the material thickness and adjust accordingly. Also, remember to maintain a steady travel speed and angle. Uneven movement can cause inconsistencies in the weld bead.

Overheating the material is a frequent issue too. It can warp the stainless steel and ruin the joint. Welders often push the heat too high out of impatience. This leads to regret once the job is finished. Using proper technique can prevent these pitfalls. Stay mindful of your actions and the metal you are working with.

Related Posts

-

Top 10 Benefits of Using Mini Spot Welding Machines for Your Projects?

-

2025 Guide: How to Choose the Best Automotive Spot Welder for Your Needs

-

2025 How to Choose the Right Resistance Spot Welder for Your Needs

-

The Ultimate Guide to Buying a MIG Welder for Your Welding Projects

-

Spot Welding Machines: Revolutionizing Manufacturing Efficiency and Quality in 2023

-

Ultimate Guide to Mobile Welding Techniques for Every DIY Enthusiast

Contact us

Please fill out the enquiry form, and our dedicated team will promptly attend to your request