Top 10 Spot Welding Machines You Should Consider for Your Projects?

When tackling various welding projects, choosing the right spot welding machine is crucial. These machines enable efficient and precise welding by joining metal parts together using heat. As technology advances, many options are available on the market, but not all are created equal. This guide explores the top 10 spot welding machines worth considering for your specific needs.

Investing in a quality spot welding machine can enhance your productivity. You want a machine that performs reliably over time. Durability and functionality are important, but so is the ease of use. Some machines can be complex and intimidating, while others are user-friendly and intuitive. You might find yourself struggling with intricate settings.

Ultimately, the right spot welding machine can transform your projects. It's not just about the machine; it's about how well it suits your specific applications. Researching the features and user experiences can be helpful. Be aware that different machines have different requirements. Your choice shouldn’t just be about brand or price; consider your unique project demands.

Advantages of Using Spot Welding Machines in Various Industries

Spot welding machines have become vital in multiple industries, including automotive and electronics. These machines offer several advantages that can enhance productivity and efficiency. According to a report by MarketsandMarkets, the global resistance welding equipment market is expected to grow from $2.4 billion in 2021 to $3.2 billion by 2026. This growth reflects the increasing adoption of spot welding in manufacturing processes.

One major advantage of spot welding is its speed. It allows for quick joining of materials, which can significantly reduce production times. For instance, car manufacturers use spot welding in assembly lines. The process can join panels in just a few milliseconds. This efficiency helps in meeting the high-demand production rates without losing quality.

Another benefit is the minimal heat affected zone. This feature preserves the integrity of the materials being welded. In many cases, this reduces the risk of warping or changing the properties of the surrounding materials. However, practitioners need to be cautious. If not monitored, inconsistent welds may occur. These can lead to structural weaknesses, which is a critical consideration, particularly in safety-sensitive industries like aviation. Careful attention to machine calibration and material selection can mitigate such risks.

Key Features to Look for in High-Quality Spot Welding Machines

When choosing a spot welding machine, consider its power. Machines with adjustable power settings allow for versatility. This is crucial for different materials. A well-rounded machine can handle both thin and thick materials effectively.

Tips: Always check the power output. Look for machines ranging from 1 to 10 kVA. This range should accommodate most project needs.

Another key feature is duty cycle. A higher duty cycle means longer operation time without overheating. Machines with 60% or more duty cycles are beneficial for extended tasks. This prevents disruptions during welding projects.

Tips: Don't overlook this feature. It can significantly affect productivity.

Ease of use is also vital. User-friendly controls and setups enhance the welding experience. Look for machines with digital displays or intuitive interfaces. These can help reduce mistakes, especially for beginners.

Tips: Test the machine if possible. Understanding its setup can prevent frustration later on.

Top 5 Brands Dominating the Spot Welding Machine Market in 2023

In 2023, the market for spot welding machines has seen significant growth. According to a recent industry report, the demand for efficient and durable welding solutions is on the rise. This can be attributed to the increasing automation in manufacturing processes and a shift toward electric vehicles. Companies that produce spot welding machines are now focusing on enhancing technology to support high-volume production.

Five leading brands dominate this landscape. They leverage advanced technology to provide machines with improved speed and precision. Machine operators benefit from features like programmable welding cycles. However, as with any technology, challenges remain. Not all machines deliver consistent results across various materials. Operators need to understand their specific applications when choosing a machine. This gap in performance highlights the need for better operator training and machine calibration.

The trend indicates that investment in quality welding machines is critical. Companies are seeking machines that not only meet current demands but are also adaptable for future projects. Understanding the strengths and weaknesses of each machine is essential. The market continues to evolve, and so do the skills required for operators to maximize their equipment.

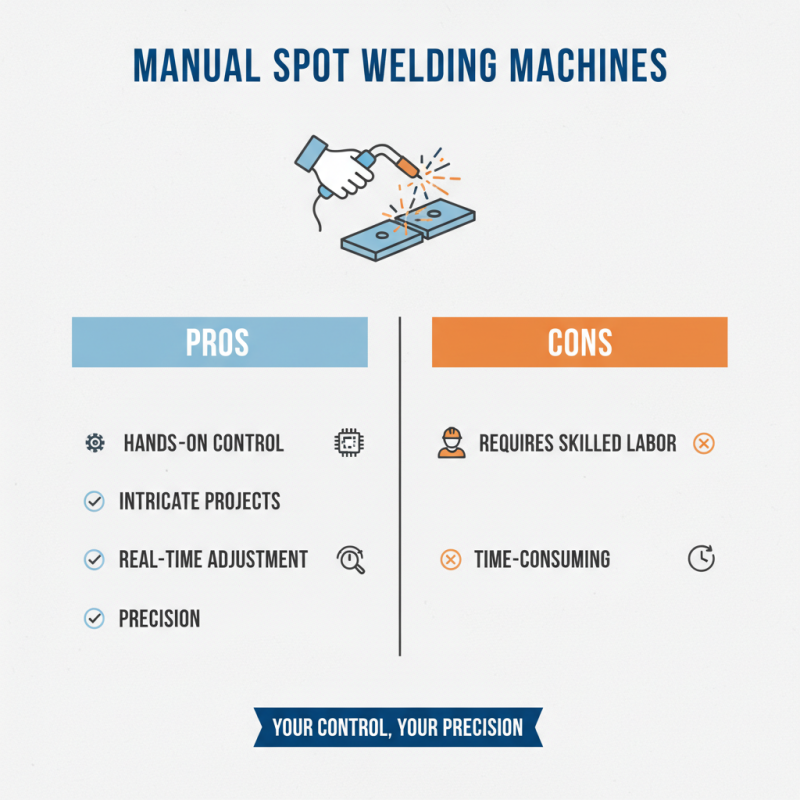

Comparison of Manual vs. Automatic Spot Welding Machines for Efficiency

When considering spot welding machines, the choice between manual and automatic options is crucial. Manual spot welding machines allow for hands-on control, which can be beneficial for intricate projects. Operators can adjust the welding process in real-time. This approach can lead to better precision. However, it does require skilled labor and can be more time-consuming.

On the other hand, automatic spot welding machines are designed for efficiency. They can handle high-volume production with consistent results. These machines reduce human error, but there is a downside. The initial investment can be significant, and maintenance is often required. Additionally, reliance on automation may overlook the tactile feedback that skilled operators provide.

Efficiency is a vital factor, but it is essential to consider project requirements. The decision should balance cost, quality, and skill availability. Each project may call for a different approach. Reflecting on these aspects can help in selecting the right spot welding machine type.

Maintenance Tips to Extend the Lifespan of Spot Welding Equipment

Maintaining spot welding equipment is crucial for its performance. Regular checks on the electrical connections are necessary. Loose connections can cause inconsistent welds. Ensure that welding tips are cleaned often. Dirt and debris can lead to poor conductivity. A simple wipe after use can make a difference.

Inspect the cooling system regularly. Overheating is a common issue with these machines. If the cooling system is blocked, it can result in damage. Look for any signs of wear and tear on cables. Replacing worn cables before they break is smart. It can prevent potential accidents and costly repairs.

Calibrate your machine as needed. Proper settings are key to successful welding. An uncalibrated machine might yield weak welds or burn holes. Keep a log of your maintenance tasks. This will help you track issues over time. Reflecting on past experiences can improve future projects. Sometimes, we overlook simple maintenance that can save us much trouble later.

Top 10 Spot Welding Machines You Should Consider for Your Projects

| Machine Model | Welding Capacity (kVA) | Electrode Force (kg) | Cycle Time (seconds) | Weight (kg) | Price Range ($) |

|---|---|---|---|---|---|

| SPW-1000 | 20 | 100 | 0.5 | 150 | 1500 - 2000 |

| WeldMaster 2000 | 25 | 120 | 0.4 | 170 | 1800 - 2300 |

| MegaWeld 300 | 30 | 200 | 0.6 | 200 | 2000 - 2600 |

| PowerWeld 400 | 35 | 250 | 0.3 | 220 | 2200 - 2800 |

| Compact Weld 500 | 40 | 150 | 0.4 | 180 | 1500 - 2000 |

| Industrial 600 | 50 | 300 | 0.5 | 250 | 3000 - 3500 |

| SmartWeld 700 | 60 | 350 | 0.4 | 320 | 3500 - 4000 |

| UltraWeld 800 | 70 | 400 | 0.6 | 400 | 4000 - 4500 |

| ProWeld 900 | 80 | 500 | 0.5 | 450 | 4500 - 5000 |

| EliteWeld 1000 | 100 | 600 | 0.3 | 500 | 5000 - 6000 |

Related Posts

-

2025 Guide: How to Choose the Best Automotive Spot Welder for Your Needs

-

Spot Welding Machines: Revolutionizing Manufacturing Efficiency and Quality in 2023

-

Why You Need a Mini Spot Welding Machine for Your DIY Projects Today

-

Understanding What a Spot Welding Machine Is and Its Applications

-

How to Choose the Best Resistance Spot Welder for Your Projects in 2025

-

2025 How to Choose the Right Resistance Spot Welder for Your Needs

Contact us

Please fill out the enquiry form, and our dedicated team will promptly attend to your request