What are the Different Types of Welders and Their Uses?

In the diverse world of welding, understanding the various types of welders is crucial. John Smith, a veteran welder with over 20 years of experience, once said, “Each welder has its purpose, shaping the fabric of our industry.” This insight highlights the importance of choosing the right type of welder for specific tasks.

Welders are not all the same. From MIG to TIG to stick welding, each method serves unique needs. For instance, MIG welders are known for their speed and ease of use. They are ideal for beginners. On the other hand, TIG welders offer precision and control, making them perfect for intricate work. Alongside these, stick welders provide versatility in outdoor conditions but require more skill. The industry’s constant evolution means new technologies emerge, and so do new challenges.

Understanding these differences is essential for any aspiring welder. Reflecting on personal experiences, it's clear that mistakes are part of the learning curve. Choosing the wrong welder can lead to frustrations. Every decision shapes the outcome of a project. Being aware of each welder's strengths and weaknesses is vital in this trade.

Types of Welders: An Overview of Common Welding Techniques

Welding is a skilled craft that comes in various forms, each suited for different tasks. Gas Metal Arc Welding (GMAW), also known as MIG welding, is a common technique. It uses a continuous wire feed to create a strong bond between metals. Beginners often find this method easier to learn. However, controlling the settings requires practice.

Shielded Metal Arc Welding (SMAW) is another popular option. It utilizes a coated electrode to create a protective gas shield. This method is often used in construction and heavy equipment repair. Its versatility makes it a favorite among welders. Yet, it demands precision and can be messy.

TIG welding, or Gas Tungsten Arc Welding, offers high-quality results. It uses a non-consumable electrode and is perfect for thin materials. Many professionals prefer TIG for intricate work. However, the learning curve is steep, and it takes time to master. Each technique has its pros and cons, and the choice depends on the specific project requirements.

What are the Different Types of Welders and Their Uses?

| Welder Type | Description | Common Uses |

|---|---|---|

| MIG Welder | Uses a continuous wire feed to weld metal. | Automotive repair, metal fabrication, and thin metal sections. |

| TIG Welder | Provides precise control with a non-consumable tungsten electrode. | Aerospace, art pieces, and thin-walled sections. |

| Stick Welder | Uses a consumable electrode coated in flux. | Construction, maintenance, and outdoor welding. |

| Flux-Cored Welder | Similar to MIG but does not require shielding gas. | Heavy-duty welding, farm equipment repair, and outdoor applications. |

| Plasma Arc Welder | Uses a plasma torch to produce a high-temperature arc. | Precise welding in thin materials, aerospace applications. |

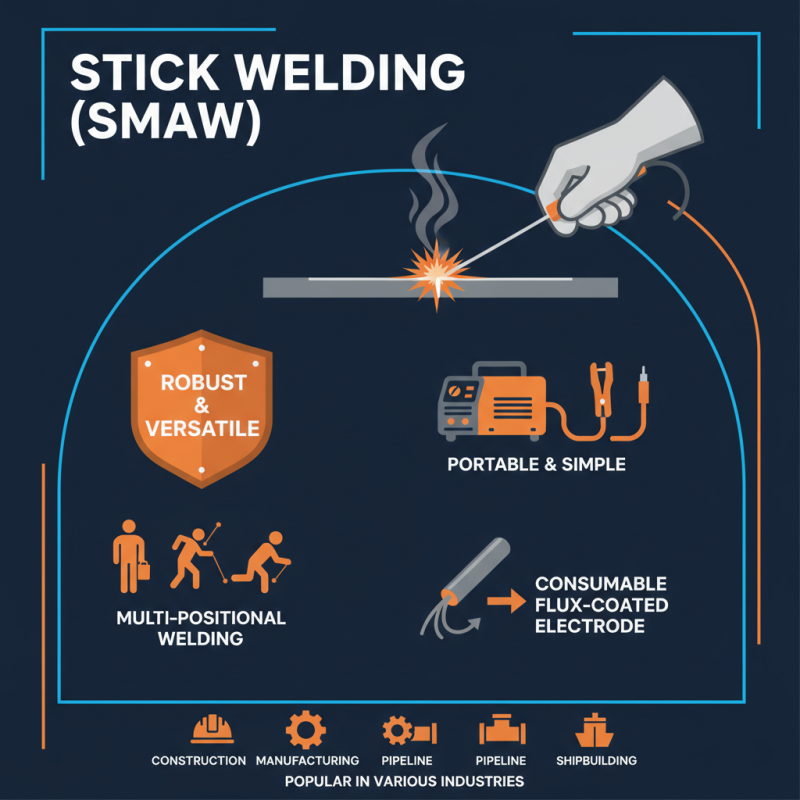

Stick Welders: Advantages and Applications in Various Industries

Stick welders, also known as Shielded Metal Arc Welders (SMAW), are popular in various industries. They use a consumable electrode coated with flux to create an arc. This method is robust and versatile. Many workers appreciate its ability to weld in different positions. The equipment is portable and simple to use.

Stick welding is widely used in construction and metal fabrication. It can join thick materials effectively. For example, projects like building frames or pipelines benefit greatly from stick welding. This method also performs well outdoors, even in windy conditions. However, it can produce more slag, which requires additional cleanup later.

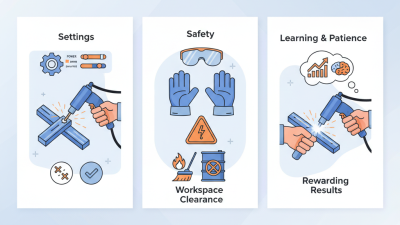

**Tips**: Always wear protective gear, including gloves and a mask. This will keep you safe from sparks and UV rays. Practice on scrap metal before tackling actual projects. Experimenting helps improve skills and confidence.

Weld quality can vary with stick welding. Issues like contamination or poor technique can lead to defects. Each weld requires attention and care. Don’t rush the process, as it might result in rework later. Take your time to perfect your technique. Learning from mistakes is crucial for improvement.

MIG Welders: How They Work and Their Popular Use Cases

MIG welders, or Metal Inert Gas welders, are popular for their versatility. These machines use a spool of wire that acts as both the electrode and filler material. The process is simpler than others, making it accessible for beginners. Many hobbyists and professionals alike appreciate their ease and efficiency. However, some users may struggle with settings and wire feed rates.

In terms of applications, MIG welders excel in various projects. They are ideal for automotive repairs, where speed and precision matter. Many metal fabricators rely on MIG technology for creating sturdy structures. However, the quality of the weld can vary among users. Inconsistent technique can lead to weak joints. Therefore, practice is essential to achieve the best results.

MIG welding is also widely used in home workshops. It allows for quick repairs and modifications. Yet, without proper safety measures, accidents can occur. New welders must be mindful of the equipment and surroundings. Recognizing the limitations of MIG welding can help users make better choices.

Types of Welders and Their Common Applications

This chart illustrates the different types of welders and their common applications in various welding scenarios. MIG welders are the most widely used, followed by TIG and Stick welders.

TIG Welders: Precision Welding for Critical Applications Explained

TIG welding, or Tungsten Inert Gas welding, is renowned for its precision. It's heavily utilized in industries like aerospace and automotive. The need for accurate welds in these fields drives TIG’s popularity. According to a 2022 industry report, up to 70% of aerospace manufacturers prefer TIG for thin materials. This method excels with aluminum and stainless steel, vital for both strength and weight reduction.

The process involves a tungsten electrode, which creates the arc. The welder uses a filler rod to add material. This technique requires skill. Even slight errors can lead to weak joints. A recent study showed that improper settings can increase failure rates by 30%. Training is essential, yet many new welders struggle with the nuances of TIG compared to MIG welding.

Another aspect is the required environment. TIG welding is sensitive to contamination. Even small amounts of oil or rust can compromise a weld. The workspace must be clean and ventilated. This requirement can prove challenging in various settings. Many industries revise their facilities to meet these standards. The pursuit of perfection in TIG welding is ongoing, and the journey comes with learning curves.

Flux-Cored Welders: Benefits and Situations for Effective Use

Flux-cored welders are popular in various welding applications. They are efficient for both indoor and outdoor use. One advantage is their ability to work in windy conditions. This feature makes them ideal for construction sites or outdoor repairs. The process utilizes a tubular wire filled with flux. This allows for smooth arc action and better penetration in thick materials.

These welders excel in projects where speed is crucial. However, they can produce more spatter compared to other methods. This may lead to a messier work area if not monitored. It's essential to practice good cleanup habits after welding. Beginners might find the learning curve challenging. But with time and practice, they can master the technique.

Conversion to flux-cored welding may not be suitable for all projects. The welds might not meet aesthetic expectations in visible areas. Hence, careful consideration is necessary before choosing this method. Understanding the environment and material helps in making the right decision. Ultimately, flux-cored welders are an effective tool for many, but results vary based on usage.

Related Posts

-

Top 5 Best Welders for every Budget in 2023: Reviews and Buyer’s Guide

-

10 Essential Tips for Welding Metal Like a Pro: Techniques and Safety

-

2026 How to Use a Spot Welding Gun Effectively in Your Projects?

-

Why is Welding Repair Essential for Structural Integrity?

-

Top Guide to Mig Welder Hire for Your Welding Projects?

-

Ultimate Guide to Mobile Welding Techniques for Every DIY Enthusiast

Contact us

Please fill out the enquiry form, and our dedicated team will promptly attend to your request