The Ultimate Guide to Buying a MIG Welder for Your Welding Projects

When embarking on welding projects, selecting the right equipment is crucial to achieving the best results. For both beginners and experienced welders, the prospect of purchasing a MIG welder can be intimidating due to the myriad of options available in the market. Understanding the key features and specifications of a MIG welder is essential before making a purchase. This guide aims to simplify the decision-making process, providing you with valuable insights on how to buy a MIG welder that perfectly suits your needs.

Whether you are planning to work on DIY projects, automotive repairs, or professional fabrications, choosing the right MIG welder can dramatically influence the quality and efficiency of your work. Factors such as power output, wire feed speed, and ease of use are integral considerations that can affect your welding experience. By familiarizing yourself with these critical aspects, you will be better equipped to make an informed choice when you decide to buy a MIG welder. Join us as we explore the essential tips and recommendations that will help you select the ideal MIG welding machine for your upcoming projects.

Understanding MIG Welding: Principles and Applications

MIG welding, or Metal Inert Gas welding, is a versatile and efficient welding process widely used in both industrial and DIY applications. The principle behind MIG welding involves feeding a continuous solid wire electrode through a welding gun, where it is melted and fuses with the base metal to create a strong joint. This process is accompanied by an inert shielding gas, often argon or a mixture of gases, which protects the molten weld pool from atmospheric contamination, ensuring a clean and robust bond.

The applications of MIG welding are extensive, making it a preferred choice for welders of all skill levels. From automotive repairs to structural fabrication, MIG welding is effective across a variety of materials, including steel, aluminum, and stainless steel. The ease of use and speed of the process allows for faster production times, making it ideal for both high-volume manufacturing and detailed artistic projects. Additionally, the adaptability of MIG welding means it can be used in various positions, whether flat, horizontal, vertical, or overhead, catering to the diverse needs of different welding projects.

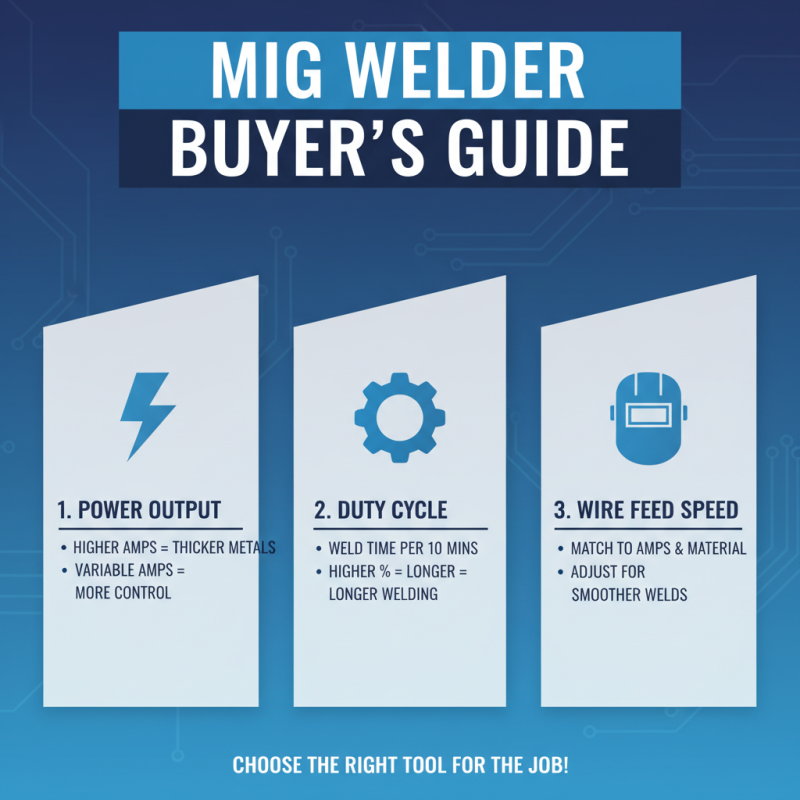

Key Features to Consider When Buying a MIG Welder

When buying a MIG welder, understanding its key features is crucial to ensure you select the right model for your welding projects. First and foremost, consider the power output of the welder. A machine with higher amperage allows you to weld thicker materials, making it suitable for a wider range of applications. Look for models that offer variable amperage settings; this will give you more control over the welding process and adaptability to different thicknesses of metal.

Another significant factor to evaluate is the welder's feed system. A reliable wire feed system is essential for smooth operation and consistent weld quality. Consider whether the welder has a solid drive mechanism, as it affects the feeding speed and ease of use. Additionally, the type and size of the wire spool it accommodates can influence the convenience and efficiency of your workflow. Safety features are also important; check for equipment with built-in thermal overload protection, which safeguards the machine from overheating and extends its lifespan.

Comparative Analysis of Popular MIG Welder Brands

When embarking on the journey to purchase a MIG welder, understanding the different brands available on the market is crucial. Each brand typically offers a range of models tailored to varying skill levels and types of projects, which influences their performance and features. A comparative analysis often reveals key distinctions in power output, duty cycles, and ease of use. For instance, some brands focus on heavier-duty machines suited for industrial applications, while others might emphasize portability and user-friendly designs for hobbyists and DIY enthusiasts.

Moreover, the build quality and durability of welding equipment can vary significantly between brands. Some manufacturers use higher-grade materials that withstand wear and tear, resulting in longer-lasting welders that can handle frequent use. Additionally, support services, such as access to replacement parts and customer service responsiveness, are vital considerations that might sway a buyer's decision. Hence, researching and comparing the reputations for reliability and service among different MIG welder brands can provide valuable insights, ensuring that the choice aligns with both project requirements and personal preferences.

The Ultimate Guide to Buying a MIG Welder for Your Welding Projects

Essential Accessories and Safety Gear for MIG Welding

When undertaking MIG welding projects, investing in the right accessories and safety gear is crucial for both effectiveness and safety. First and foremost, a high-quality welding helmet is essential. Look for one that provides adequate UV and IR protection, features auto-darkening capabilities, and is comfortable to wear for extended periods. Additionally, consider a pair of welding gloves made from durable materials that offer both protection from heat and flexibility for better control during the welding process. A fire-resistant jacket is also a must-have, as it will shield your skin from sparks and heat.

Tips: Always ensure that your safety gear fits properly to maximize effectiveness and comfort. Regularly check your equipment for wear and tear, and replace items as necessary to maintain a high level of safety.

In addition to protective clothing, having the right tools can enhance your MIG welding experience. A welding cart can help keep your welder and supplies organized and easily accessible. Gas cylinders should be properly strapped and stored securely, while a nozzle cleaning kit can ensure your welder operates optimally. Don't forget a good pair of safety glasses to provide additional eye protection during setups and adjustments.

Tips: Invest in quality tools rather than trying to save money on cheaper options. This can improve your overall experience and ensure longer-lasting performance.

Maintenance Tips for Prolonging the Life of Your MIG Welder

Maintaining your MIG welder is essential for ensuring its longevity and optimal performance. Regular maintenance can extend the life of your welder by 50% or more, according to findings from the American Welding Society. Simple upkeep tasks such as cleaning the nozzle and tip after every use, regularly inspecting the cable and wire feed, and keeping the machine free of dust and debris can lead to significant improvements in efficiency and reduce the likelihood of costly repairs. It's also recommended to periodically replace worn-out parts, like contact tips, to prevent productivity losses.

Another important aspect of maintenance is proper care of the gas supply. Moisture in shielding gas can cause welding defects and adversely affect weld quality. Data from the Fabricators and Manufacturers Association highlights that maintaining the integrity of gas cylinders and ensuring proper connections can mitigate these issues. Furthermore, storing the welder in a stable environment where temperature and humidity levels are controlled helps protect internal components, ultimately preserving both functionality and welding quality. Adhering to these maintenance tips not only enhances the performance of your MIG welder but also ensures that your welding projects meet industry standards for durability and reliability.

Related Posts

-

Top Tips for Choosing the Best MIG Welder in 2025 for Your Projects

-

Understanding the Essential Components of MIG Welding Equipment for Beginners

-

How to Choose the Best Cheap Mig Welder for Your Welding Projects

-

Ultimate Guide to Buy Mig Welder Tips for Beginners and Experts

-

The Science Behind Welding Metal Techniques for Stronger Fabrications

-

Best Mini Spot Welding Machine for Efficient and Precise Metal Joining

Contact us

Please fill out the enquiry form, and our dedicated team will promptly attend to your request